Qhov xav tau ntawm qhov project

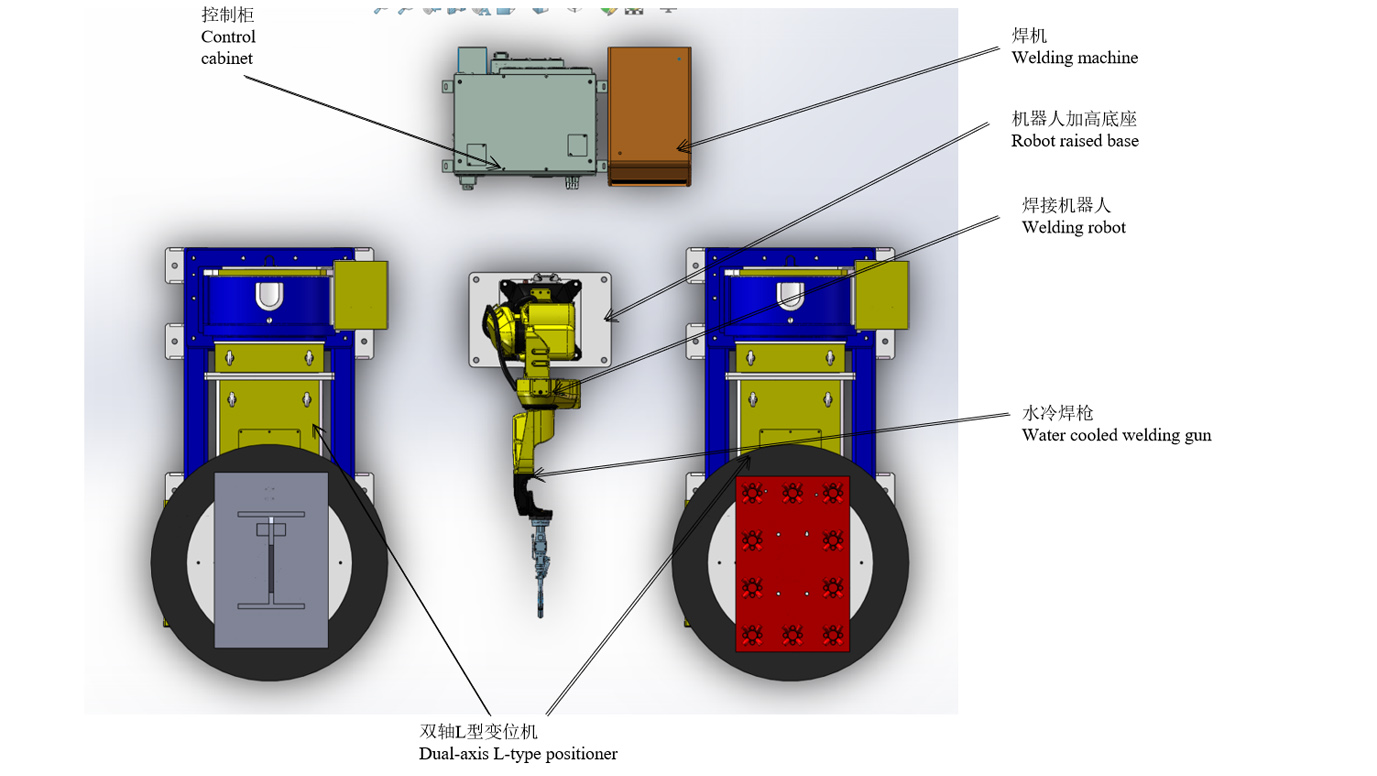

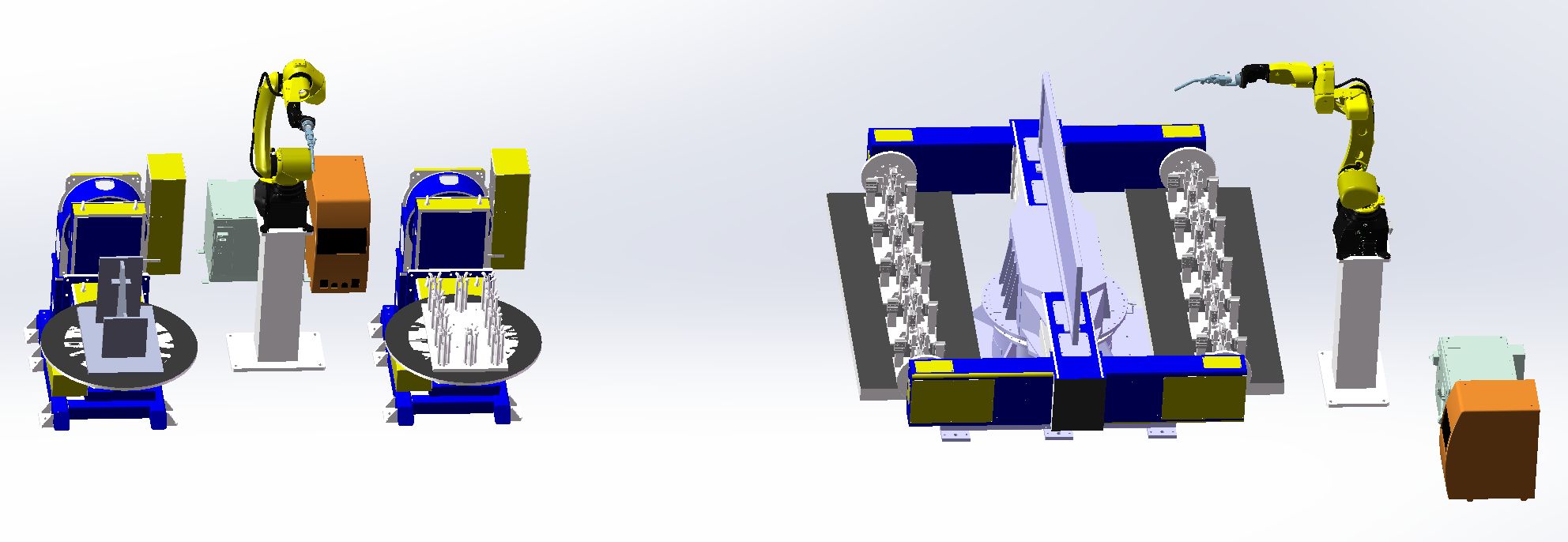

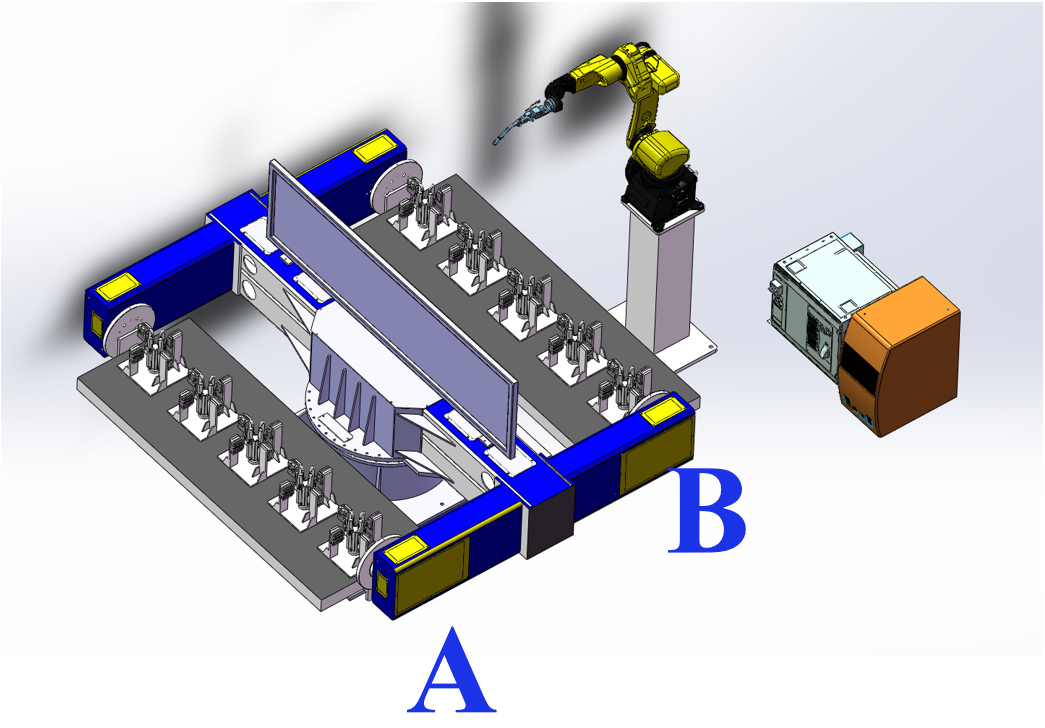

Zuag qhia tag nrho Layout & 3D qauv

Lus Cim: Daim duab kos duab tsuas yog siv rau kev kos duab kos duab thiab tsis sawv cev rau lub cev ntawm cov khoom siv. Qhov loj me yuav tsum raug txiav txim raws li tus neeg siv khoom qhov chaw.

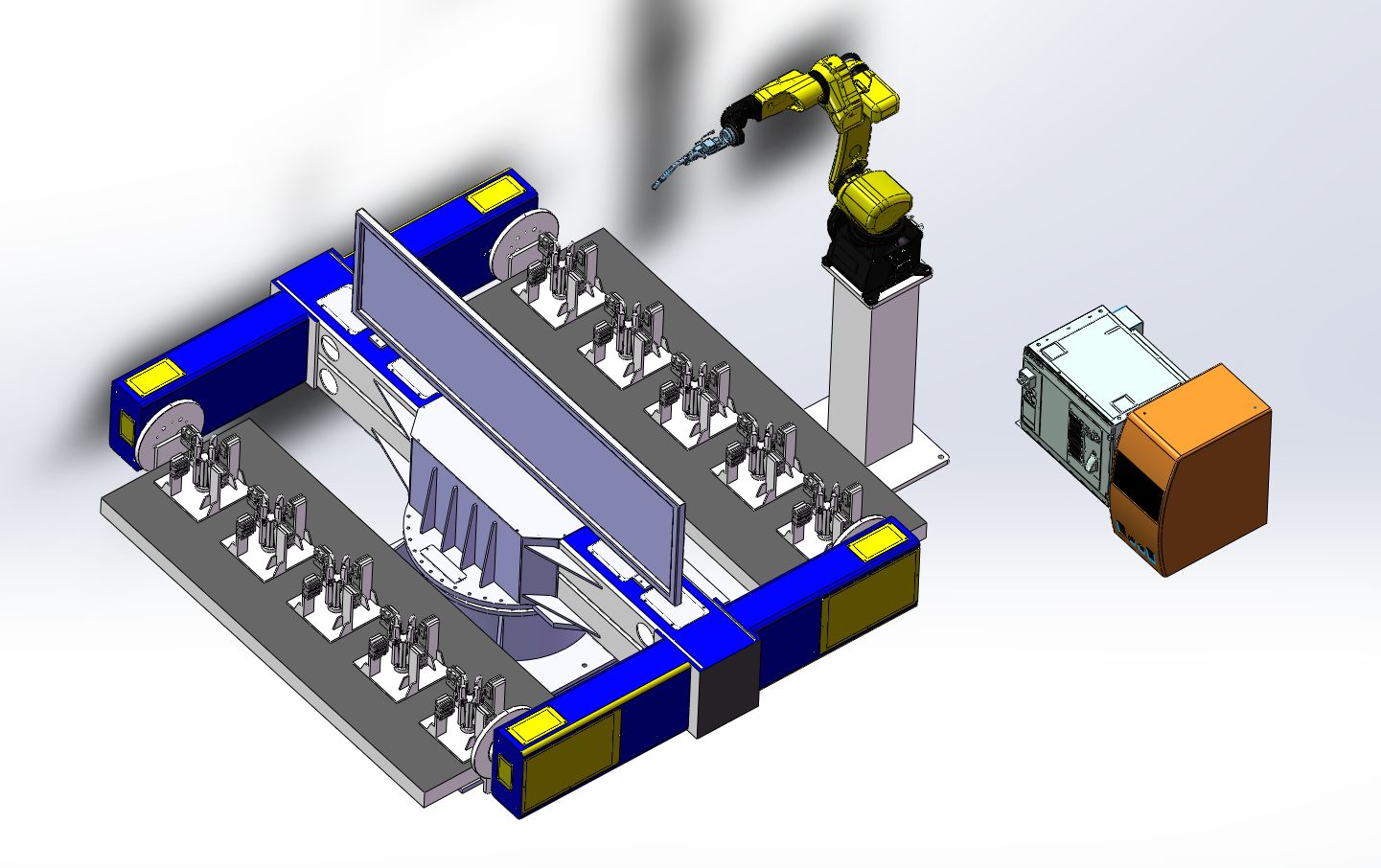

Workpiece lub cev kos duab & 3D qauv

Workpiece lub cev kos duab & 3D qauv

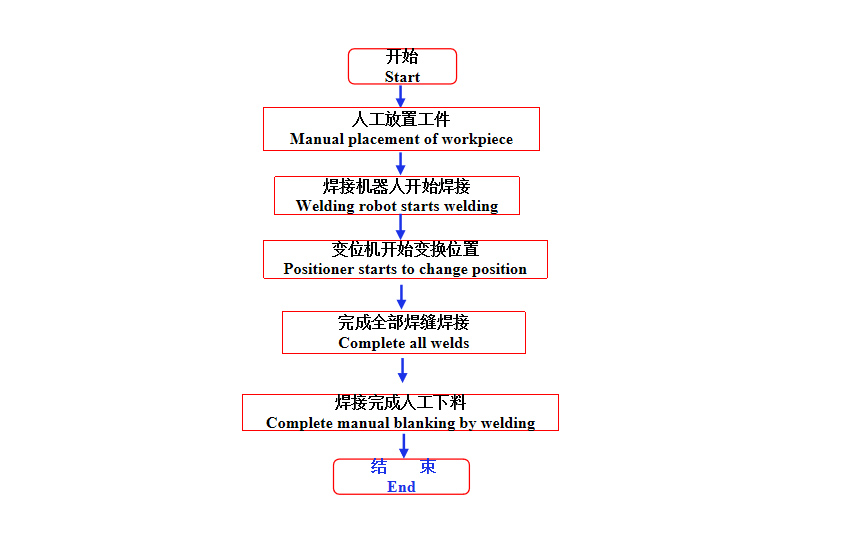

Kev ua haujlwm

Cov xwm txheej rau kev ua haujlwm ntawm chaw ua haujlwm

(1) Manually tso lub workpiece nyob rau hauv lub positioner thiab kho nws raws li yuav tsum tau.

(2) Tom qab tag nrho cov khoom siv tau qhib thiab tsis muaj lub tswb tshwm sim, npaj txhij rau kev teeb tsa.

(3) Cov neeg hlau nres ntawm qhov chaw ua haujlwm, thiab kev khiav haujlwm ntawm cov neeg hlau yog cov kev pabcuam tsim khoom.

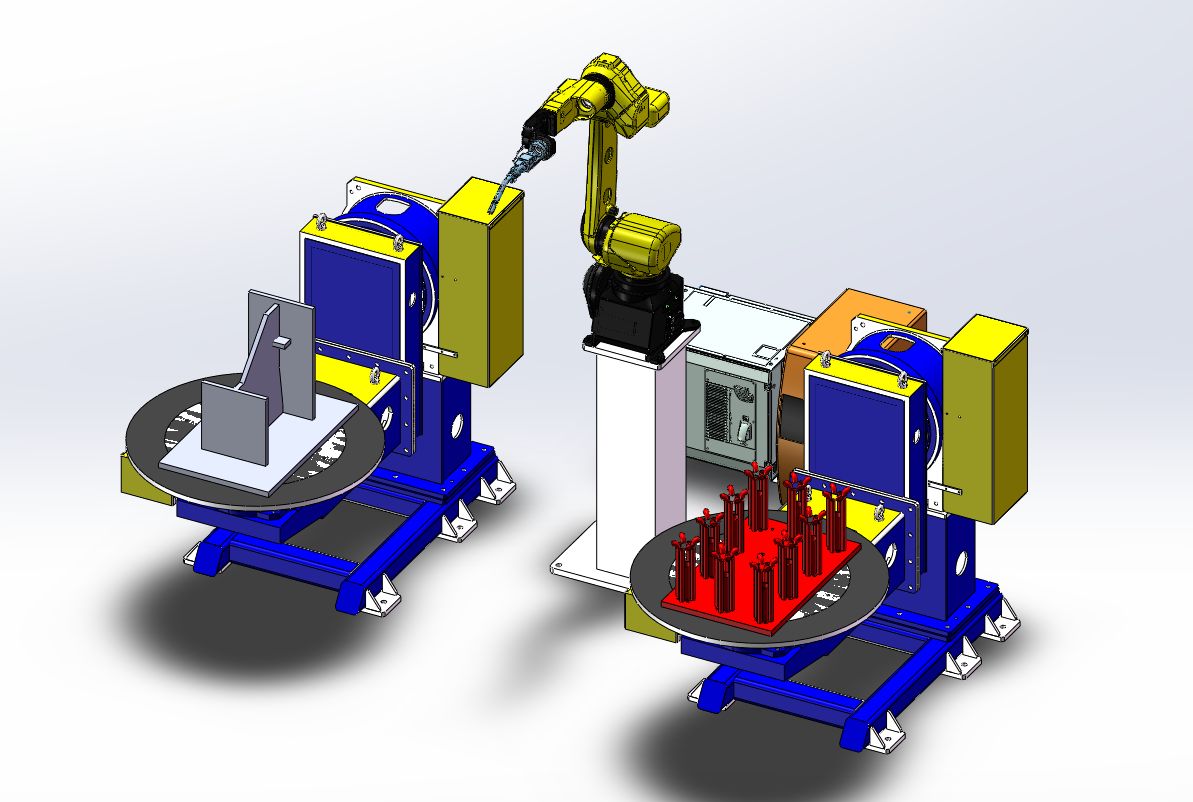

Vuam txheej txheem ntawm lub tes tsho subassembly

1. Manually nruab tsib lub tes tsho ntawm sab A.

2. Rov qab mus rau qhov chaw nyab xeeb manually thiab pib khawm clamp lub tog raj kheej kom nruj workpiece.

3. Lub positioner tig mus txog thaum tus neeg hlau ntawm sab B pib vuam.

4. Manually tshem tawm cov workpieces welded rau sab A, thiab ces tsib txheej ntawm nruas qhov chaw.

5. Lub voj voog ua haujlwm ntawm cov kev txuas saum toj no.

Lub sijhawm vuam rau txhua lub tes tsho yog 3min (suav nrog lub sijhawm teeb tsa), thiab lub sijhawm vuam ntawm 10 teeb yog 30min.

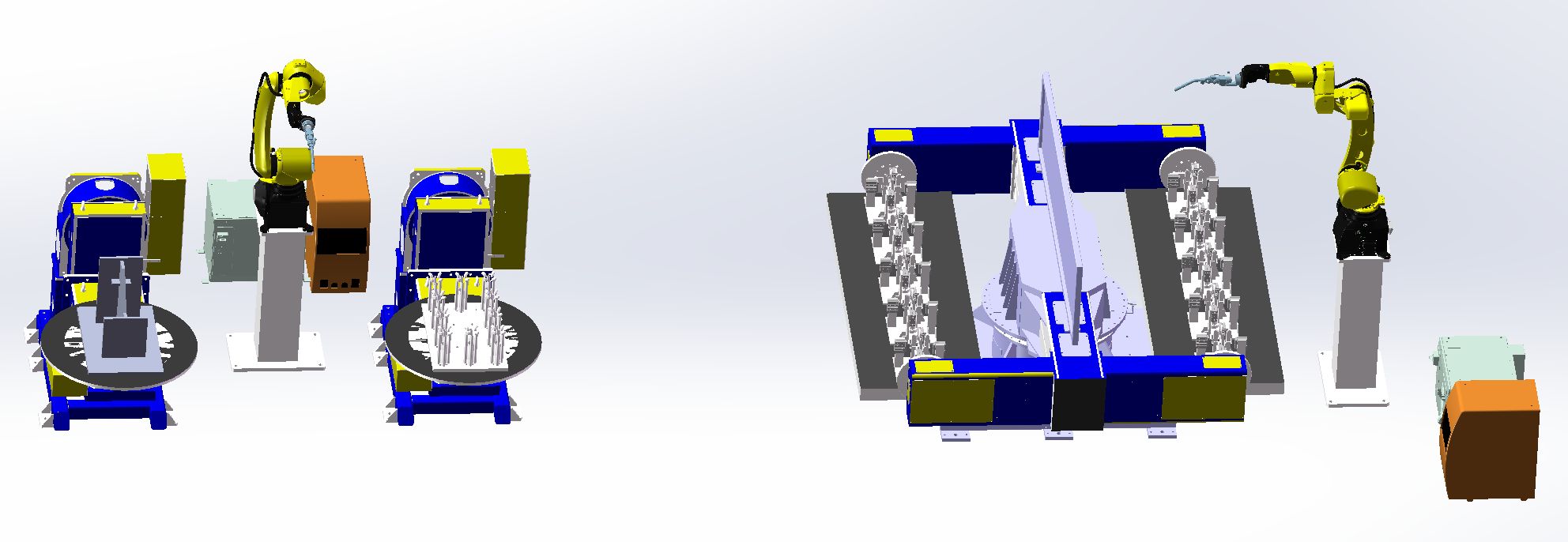

Vuam txheej txheem ntawm embedded phaj sib dhos + lub tes tsho sib dhos

1. Manually nruab lub pre-pointed embedded phaj ntawm L-hom positioner ntawm sab A.

2. Pib khawm neeg hlau vuam embedded phaj sib dhos (15min/set). 3.

3. Manually nruab qhov xoob ntawm lub tes tsho los ua ke ntawm L-hom positioner ntawm sab B.

4. Cov neeg hlau txuas ntxiv txuas lub tes tsho sib dhos tom qab vuam cov phaj sib dhos (lub tes tsho vuam rau 10min + phau ntawv nruab ntawm workpiece thiab neeg hlau qhov chaw vuam rau 5min)

5. Tshem tawm cov phaj embedded los ua ke manually.

6. Kev tuav vuam ntawm embedded phaj sib dhos (tshem tawm-qhov chaw vuam-loading hauv 15min)

7. Manually nruab lub pre-pointed embedded phaj ntawm L-hom positioner ntawm sab A.

8. Tshem tawm lub tes tsho welded los ua ke thiab nruab cov khoom seem

9. Lub voj voog ua haujlwm ntawm cov ntawv txuas saum toj no.

Vuam tiav lub sij hawm ntawm embedded phaj yog 15min + vuam ua tiav lub tes tsho sib dhos yog 15min.

Tag nrho lub sij hawm 30 min

Taw qhia ntawm Tong Hloov Ntaus

Lub sijhawm vuam ntawm cov neeg hlau ntawm cov lus hais saum toj no yog qhov txaus tshaj plaws yam tsis tau nres. Raws li 8 teev nyob rau ib hnub thiab ob tus neeg ua haujlwm, cov khoom tsim tawm ntawm ob lub rooj sib txoos tag nrho 32 teev ib hnub.

Txhawm rau nce cov zis:

Ib tus neeg hlau tau ntxiv rau peb-axis positioner ntawm lub tes tsho subassembly chaw nres tsheb thiab hloov mus rau ob lub tshuab vuam. Nyob rau tib lub sijhawm, lub embedded phaj sib dhos + lub tes tsho sib dhos chaw nres tsheb kuj yuav tsum tau ntxiv ob pawg L-hom positioner thiab ib pawg neeg hlau. Nyob rau 8-teev hnub thiab peb tus neeg ua haujlwm hauv paus, cov khoom tsim tawm ntawm ob lub rooj sib txoos tag nrho 64 teev ib hnub.

Cov npe khoom siv

| Yam khoom | S/N | Lub npe | Qty. | Nco tseg |

| Cov neeg hlau | 1 | RH06A3-1490 | 2set ib | Muab los ntawm Chen Xuan |

| 2 | Neeg hlau tswj txee | 2set ib | ||

| 3 | Neeg hlau tsa lub hauv paus | 2set ib | ||

| 4 | Dej txias vuam phom | 2set ib | ||

| Cov khoom siv peripheral | 5 | Vuam Hwj chim Source MAG-500 | 2set ib | Muab los ntawm Chen Xuan |

| 6 | Dual-axis L-hom positioner | 2set ib | ||

| 7 | Peb-axis kab rov tav rotary positioner | 1set ib | Muab los ntawm Chen Xuan | |

| 8 | Khoom siv | 1set ib | ||

| 9 | Phom Cleaner | Teeb | xaiv tau | |

| 10 | Cov khoom siv tshem tawm plua plav | 2set ib | ||

| 11 | laj kab kev nyab xeeb | 2set ib | ||

| Cov kev pabcuam cuam tshuam | 12 | Installation thiab commissioning | 1 yam | |

| 13 | Ntim thiab thauj | 1 yam | ||

| 14 | Kev cob qhia txuj ci | 1 yam |

Technical Specification

Built-in dej txias welding phom

1) Txhua rab phom vuam yuav tsum dhau los ntawm kev ntsuas ternary kom paub meej qhov tseeb;

2) R ib feem ntawm vuam phom yog tsim los ntawm cov ntaub ntub dej casting txoj kev, uas yuav tsis deformed vim kub siab generated los ntawm vuam;

3) Txawm hais tias rab phom vuam tsoo nrog cov khoom ua haujlwm thiab cov khoom siv thaum lub sijhawm ua haujlwm, cov phom vuam yuav tsis khoov thiab tsis tas yuav tsum tau kho dua tshiab;

4) Txhim kho cov nyhuv rectifier ntawm shielding gas;

5) Qhov tseeb ntawm ib lub thoob yog nyob rau hauv 0.05;

6) Daim duab no yog siv rau kev siv xwb, thiab nws raug xaiv kawg.

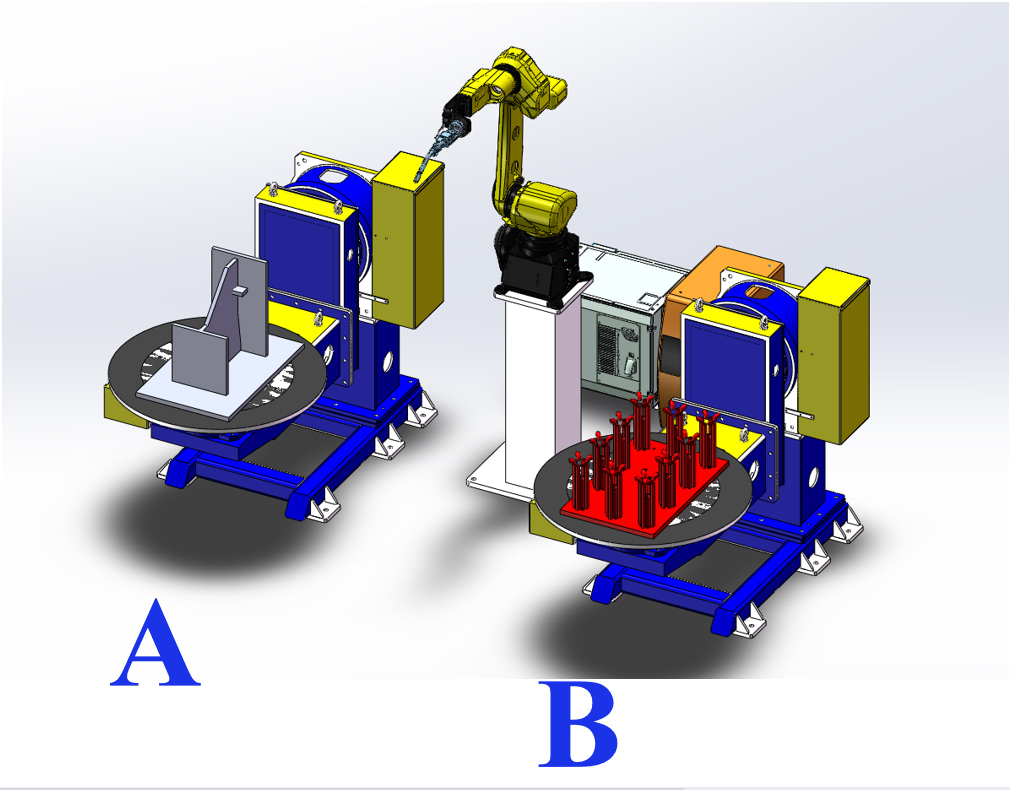

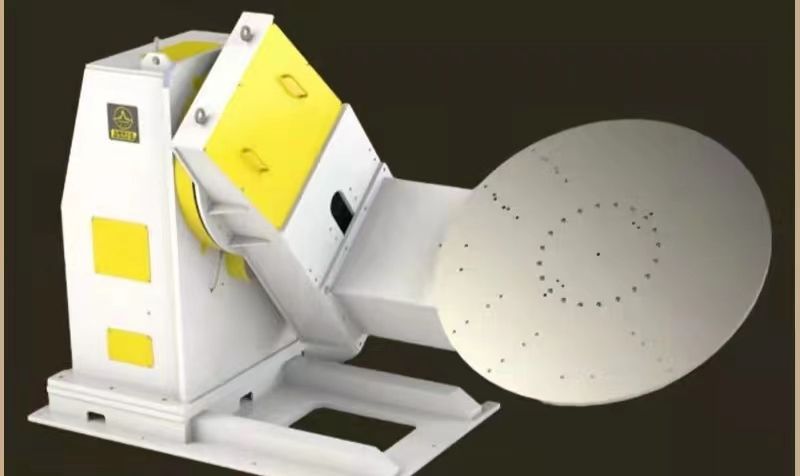

Dual-axis L-hom positioner

Positioner yog tshwj xeeb vuam auxiliary cov cuab yeej, uas yog tsim rau vuam hloov chaw ntawm rotary ua hauj lwm, thiaj li mus tau zoo tagnrho machining txoj hauj lwm thiab vuam ceev. Nws tuaj yeem siv nrog kev tswj xyuas thiab vuam tshuab los tsim qhov chaw vuam tsis siv neeg, thiab tuaj yeem siv rau kev hloov pauv ntawm cov khoom siv thaum lub sijhawm ua haujlwm. Cov zis tsis sib xws nrog qhov sib txawv-zaus tsav yog saws rau kev sib hloov ua haujlwm, nrog kev ua haujlwm siab ntawm kev tswj ceev. Cov chaw taws teeb tswj lub thawv tuaj yeem paub cov chaw taws teeb ntawm kev ua haujlwm, thiab tseem tuaj yeem txuas nrog kev tswj hwm thiab vuam tshuab tswj kom paub txog kev ua haujlwm txuas. Lub vuam positioner feem ntau yog tsim los ntawm cov txheej txheem teb thiab tig rov ua haujlwm ntawm lub rooj zaum ua haujlwm. Lub workpiece tsau ntawm lub workbench tuaj yeem ncav cuag qhov xav tau vuam thiab sib dhos lub kaum sab xis los ntawm kev nqa, tig thiab tig ntawm lub rooj zaum ua haujlwm. Lub workbench tig mus rau hauv qhov sib txawv zaus stepless ceev tswj, uas tuaj yeem tau txais kev txaus siab vuam ceev.

Cov duab tsuas yog siv rau kev siv xwb, thiab nws yuav raug tsim los zaum kawg.

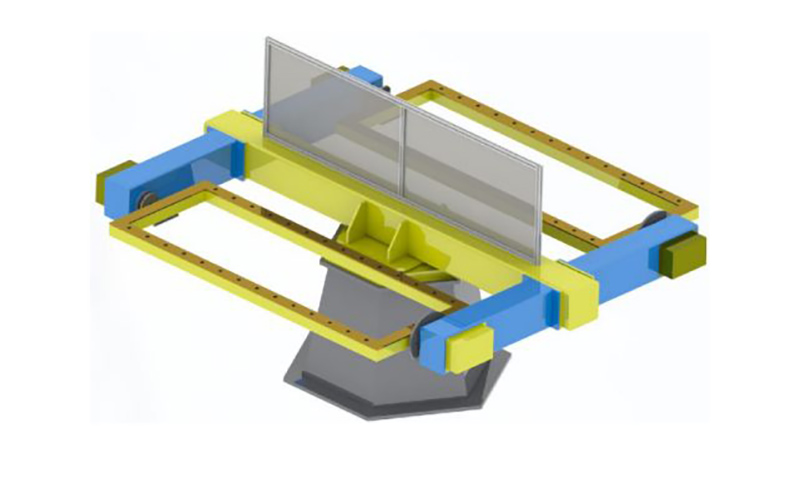

Peb-axis kab rov tav rotary positioner

1) Peb-axis kab rov tav rotary positioner feem ntau yog tsim los ntawm ib qho chaw ruaj khov, lub thawv spindle thiab lub thawv, vuam ncej, servo motor thiab precision reducer, conductive mechanism, tiv thaiv npog thiab hluav taws xob tswj system, thiab lwm yam.

2) Los ntawm kev teeb tsa sib txawv servo motors, lub positioner tuaj yeem ua haujlwm nyob deb ntawm tus kws qhia neeg hlau lossis lub thawv ua haujlwm sab nraud;

3) Qhov xav tau vuam thiab sib dhos lub kaum ntse ntse yog ua tiav los ntawm kev tig lub workpiece tsau rau ntawm qhov chaw ua haujlwm;

4) Kev sib hloov ntawm lub workbench yog tswj los ntawm servo lub cev muaj zog, uas tuaj yeem ua tiav qhov zoo tshaj plaws vuam ceev;

5) Cov duab yog rau kev siv nkaus xwb, thiab nws yuav raug tsim los zaum kawg;

Vuam fais fab mov

Nws yog tsim rau splicing, lapping, ces kaum sib koom tes, raj phaj taub qab sib koom, kev sib tshuam kab kev sib txuas thiab lwm yam kev sib koom ua ke, thiab tuaj yeem paub txhua txoj haujlwm vuam.

Kev nyab xeeb thiab kev ntseeg siab

Lub tshuab vuam thiab xaim feeder tau nruab nrog kev tiv thaiv dhau tam sim no, dhau-voltage thiab tiv thaiv kub dhau. Lawv tau dhau los ntawm EMC thiab kev ntsuas hluav taws xob uas xav tau los ntawm lub teb chaws tus qauv GB / T 15579, thiab dhau 3C ntawv pov thawj los xyuas kom muaj kev ntseeg siab thiab kev nyab xeeb hauv kev siv.

Kev txuag hluav taws xob thiab kev tiv thaiv ib puag ncig

Lub sij hawm nrhiav tau roj, ua ntej lub sij hawm muab roj thiab lag luam roj lub sij hawm yog kho tau los xyuas kom meej tias cov roj siv tsim nyog. Thaum lub tshuab vuam siv lub tshuab fais fab, yog tias nws tsis nkag mus rau hauv lub vuam lub xeev tsis pub dhau 2 feeb (lub sij hawm adjustable), nws yuav cia li nkag mus rau hauv lub xeev pw tsaug zog. Tua lub kiv cua thiab txo cov kev siv zog.

Daim duab no yog siv rau kev siv xwb, thiab nws yuav raug xaiv zaum kawg.

Vuam fais fab mov

Phom tu thiab silicone roj txau cov cuab yeej thiab cov khoom siv hlau txiav

1) Silicone roj txau cov cuab yeej ntawm rab phom ntxuav qhov chaw txais yuav ob lub nozzle rau cross spraying, kom cov roj silicone tuaj yeem ncav cuag lub puab nto ntawm vuam torch nozzle zoo dua thiab xyuas kom meej tias vuam slag yuav tsis ua raws li lub nozzle.

2) Cov phom ntxuav thiab cov roj silicone txau yog tsim los ntawm tib txoj haujlwm, thiab cov neeg hlau tuaj yeem ua tiav cov txheej txheem ntawm silicone roj txau thiab rab phom ntxuav nrog tsuas yog ib qho kev ua.

3) Nyob rau hauv cov nqe lus ntawm kev tswj, rab phom tu thiab silicone roj txau cov cuab yeej tsuas yog xav tau lub teeb liab pib, thiab nws tuaj yeem pib ua raws li qhov kev txiav txim ua ntu zus.

4) Cov khoom siv hlau txiav tau txais cov qauv siv tus kheej ntawm cov phom vuam, uas tshem tawm qhov xav tau siv cov solenoid li qub los tswj nws thiab ua kom yooj yim rau cov hluav taws xob larrangement.

5) Cov cuab yeej txiav hlau tuaj yeem muab cais los yog ntsia ntawm rab phom ntxuav thiab cov roj silicone txau los ua ib qho khoom siv sib xyaw, uas tsis tsuas yog txuag qhov chaw teeb tsa, tab sis kuj ua rau kev teeb tsa thiab kev tswj cov roj txoj kev yooj yim heev.

6) Daim duab no yog siv rau kev siv xwb, thiab nws raug xaiv kawg.

Kev ruaj ntseg laj kab

1. Teem lub laj kab kev tiv thaiv, lub qhov rooj ruaj ntseg lossis kev ruaj ntseg gratings, kev ruaj ntseg xauv thiab lwm yam khoom siv, thiab ua kom muaj kev tiv thaiv kev cuam tshuam.

2. Lub qhov rooj ruaj ntseg yuav tsum tau teem rau ntawm qhov chaw ntawm lub laj kab tiv thaiv. Txhua lub qhov rooj yuav tsum tau nruab nrog kev nyab xeeb hloov thiab cov nyees khawm, pib dua khawm thiab khawm nres thaum muaj xwm ceev.

3. Lub qhov rooj kev ruaj ntseg yog interlocked nrog lub kaw lus los ntawm kev ruaj ntseg xauv (hloov). Thaum lub qhov rooj ruaj ntseg qhib qhov txawv txav, lub kaw lus nres ua haujlwm thiab muab lub tswb.

4. Kev tiv thaiv kev nyab xeeb tau lees paub kev nyab xeeb ntawm cov neeg ua haujlwm thiab cov khoom siv los ntawm kev kho vajtse thiab software.

5. Lub laj kab kev nyab xeeb tuaj yeem muab los ntawm Party A nws tus kheej. Nws raug pom zoo kom siv daim phiaj vuam zoo thiab ci daj ceeb toom xim rau ntawm qhov chaw.

Hluav taws xob tswj System

1. suav nrog kev tswj hwm thiab teeb liab kev sib txuas lus ntawm cov khoom siv, nrog rau cov sensors, cables, slots, keyboards, thiab lwm yam;

2. Lub tshuab tsis siv neeg yog tsim los nrog peb-xim tswb lub teeb. Thaum lub sijhawm ua haujlwm ib txwm muaj, lub teeb peb xim qhia ntsuab; yog tias chav tsev ua tsis tiav, lub teeb peb-xim yuav pom lub tswb liab hauv lub sijhawm;

3. Muaj cov nyees khawm nres thaum muaj xwm ceev ntawm cov neeg hlau tswj txee thiab lub thawv qhia. Thaum muaj xwm txheej ceev, lub khawm nres xwm ceev tuaj yeem nias kom paub txog qhov nres xwm ceev ntawm lub kaw lus thiab xa tawm lub tswb nrov tib lub sijhawm;

4. Ntau yam ntawm cov ntawv thov tuaj yeem muab tso ua ke los ntawm cov khoom siv qhia ntawv, ntau daim ntawv thov tuaj yeem muab tso ua ke, uas tuaj yeem ua tau raws li qhov yuav tsum tau ua ntawm kev hloov kho cov khoom thiab cov khoom tshiab;

5. Tag nrho cov teeb liab nres thaum muaj xwm txheej ceev ntawm tag nrho cov kev tswj hwm thiab kev ruaj ntseg interlock teeb liab ntawm cov khoom siv thiab cov neeg hlau txuas nrog kev ruaj ntseg thiab cuam tshuam los ntawm kev tswj hwm;

6. Lub kaw lus tswj kom paub txog cov teeb liab kev sib txuas ntawm cov khoom siv ua haujlwm xws li neeg hlau, chaw thau khoom, gripper thiab machining cov cuab yeej.

7. Tshuab cuab tam system yuav tsum tau paub cov teeb liab pauv nrog neeg hlau system.

Kev khiav hauj lwm ib puag ncig (muab los ntawm tog A)

| Fais fab mov | Fais fab mov: peb-theem plaub-xaim AC380V ± 10%, voltage hloov pauv ntau yam ± 10%, zaus: 50Hz; Lub hwj chim ntawm cov neeg hlau tswj txee yuav tsum tau nruab nrog kev hloov pauv huab cua; Neeg hlau tswj txee yuav tsum tau grounded nrog grounding kuj tsawg dua 10Ω; Qhov kev ncua deb ntawm cov khoom siv hluav taws xob thiab cov neeg hlau hluav taws xob tswj txee yog nyob rau hauv 5 meters. |

| Cua qhov chaw | Cov cua compressed yuav tsum tau lim kom tshem tawm cov dej noo thiab impurities, thiab cov zis siab tom qab dhau los ntawm triplet yuav tsum yog 0.5 ~ 0.8Mpa; Qhov kev ncua deb ntawm huab cua thiab lub cev neeg hlau yog nyob rau hauv 5 meters. |

| Foundation | Cov pa cement pem teb ntawm Party A lub rooj cob qhia yuav tsum tau siv rau kev kho mob, thiab cov hauv paus kev teeb tsa ntawm txhua yam khoom siv yuav tsum raug kho rau hauv av nrog kev nthuav dav bolts; Pob zeb muaj zog: 210 kg / cm 2; Thickness ntawm pob zeb: ntau dua 150 mm; Lub hauv paus tsis sib xws: tsawg dua ± 3mm. |

| Ib puag ncig tej yam kev mob | ambient kub: 0 ~ 45 ° C; txheeb ze humidity: 20% ~ 75% RH (tsis condensation); Kev vibration acceleration: tsawg dua 0.5G |

| Lwm yam | Tsis txhob muaj cov pa taws thiab corrosive, thiab tsis txhob txaws roj, dej, plua plav, thiab lwm yam; Khaws kom deb ntawm qhov chaw ntawm hluav taws xob. |