Qhov project Overview

1. Kev Pabcuam Ntau Lawm

600 teeb / hnub (117/118 bearing pedestral)

2. Yuav tsum tau ua cov kab:

1) NC machining chaw tsim nyog rau cov kab ntau lawm;

2) Hydraulic frock clamp;

3) Tsis siv neeg loading thiab blanking ntaus ntawv thiab conveying ntaus ntawv;

4) Kev siv thev naus laus zis tag nrho thiab lub sijhawm ua haujlwm;

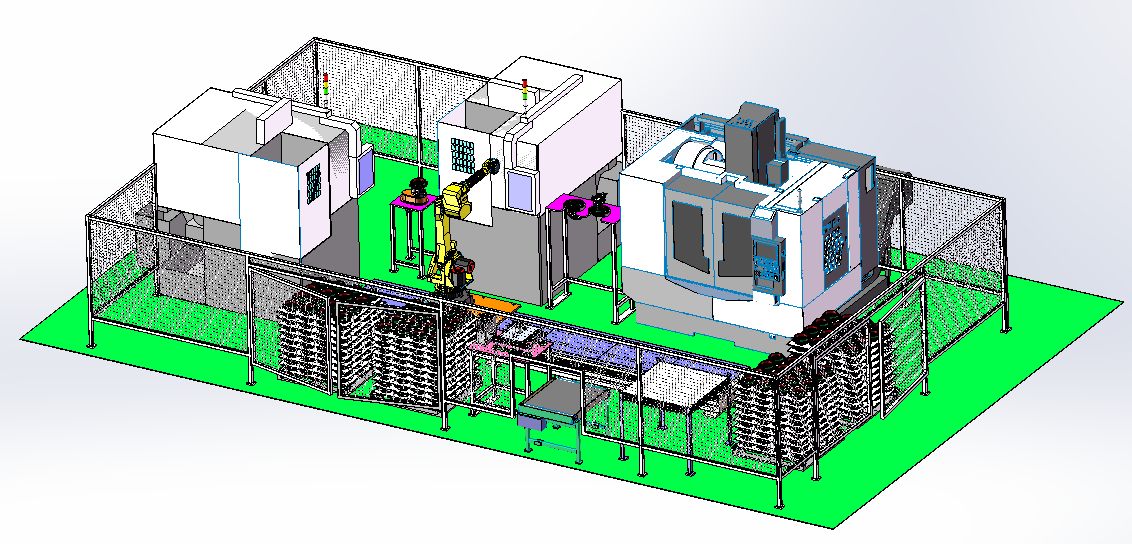

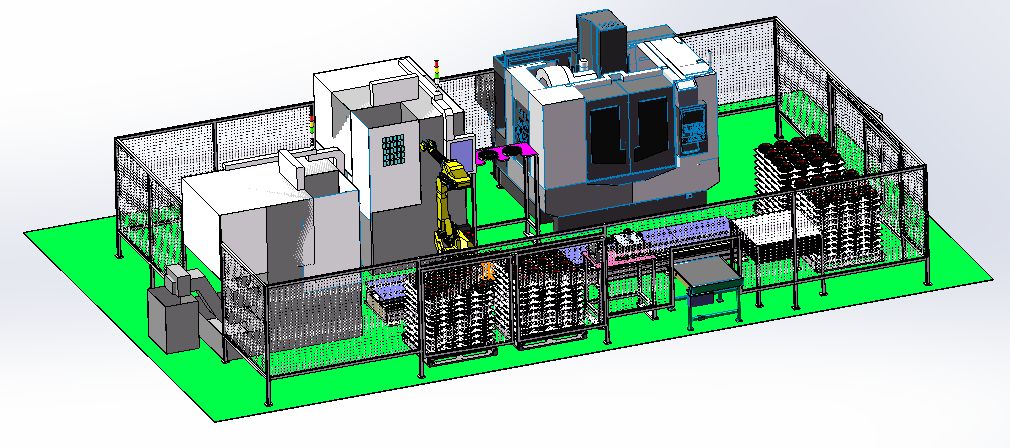

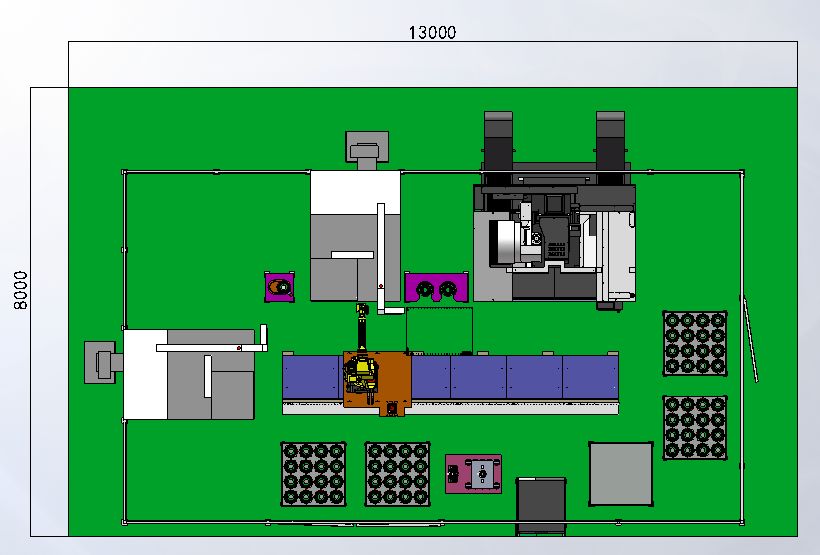

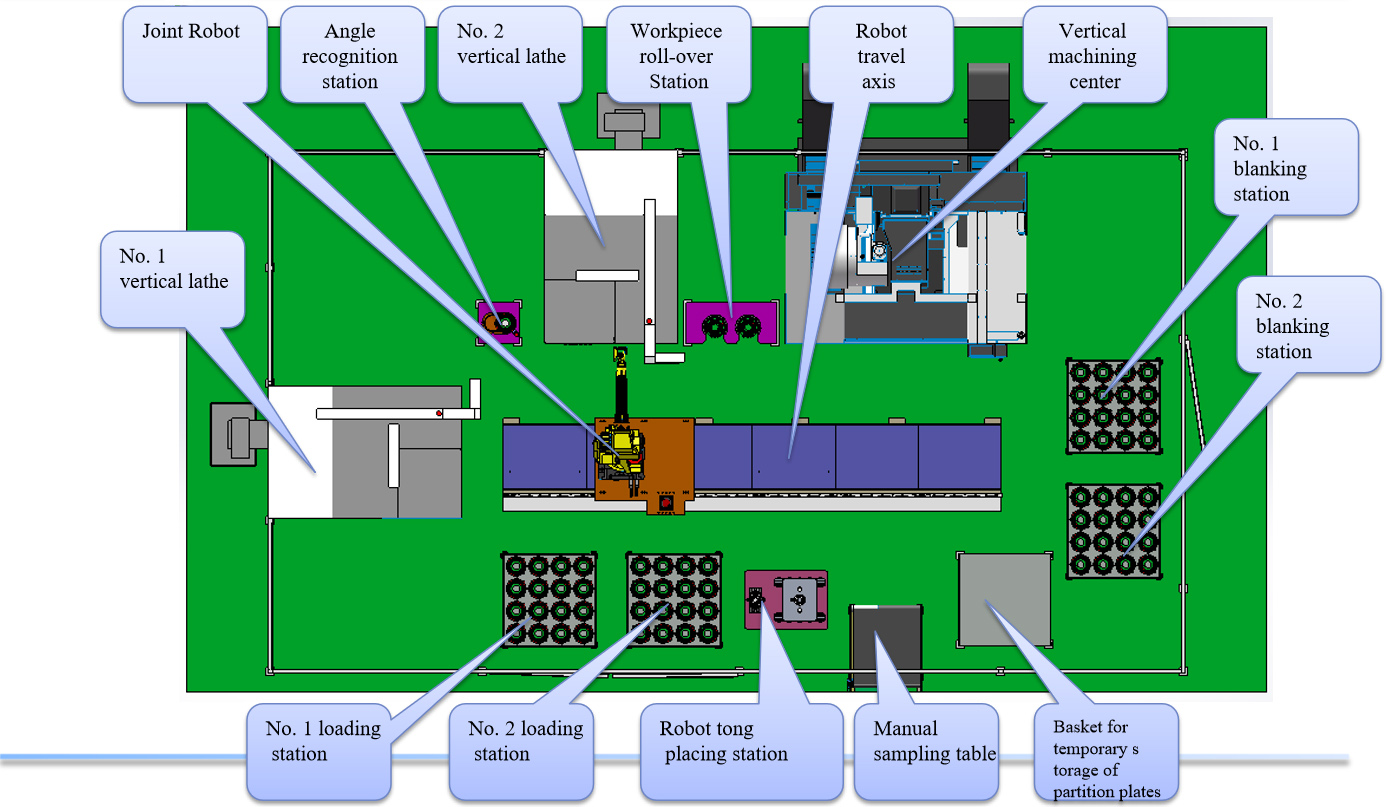

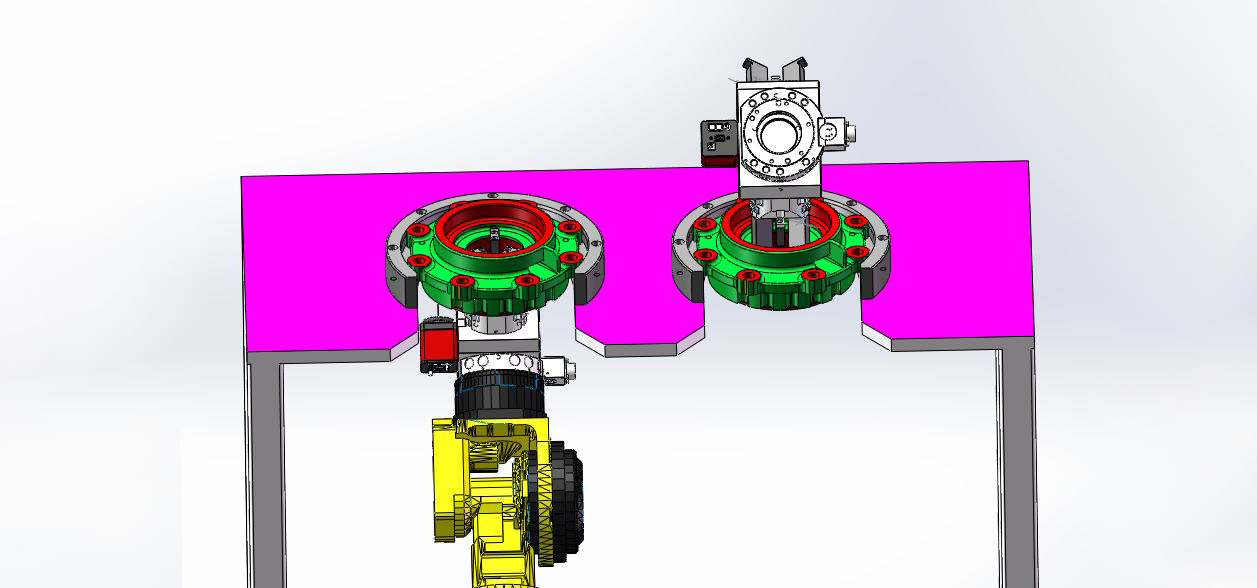

Layout ntawm Cov Kab Ntau Lawm

Layout ntawm Cov Kab Ntau Lawm

Taw qhia ntawm Robot Actions:

1. Manually muab cov khoom sib npaug thiab muab cov pob tawb tso rau ntawm lub rooj thauj khoom (Loading tables No. 1 thiab No. 2) thiab nias lub pob kom paub meej;

2. Cov neeg hlau txav mus rau lub tais ntawm No. 1 lub rooj thauj khoom, qhib lub zeem muag, rub thiab txav mus rau ntu A thiab B raws li qhov chaw saib lub kaum sab xis kom tos cov lus qhia thauj khoom;

3. Cov lus qhia thauj khoom raug xa tawm los ntawm qhov chaw nres tsheb angular lees paub. Tus neeg hlau muab No. 1 daim rau hauv qhov chaw ntawm lub turntable. Tig lub turntable thiab pib lub angular recognition system, txiav txim siab lub angular txoj hauj lwm, nres lub turntable thiab ua kom tiav lub angular recognition ntawm No. 1 daim;

4. Lub angular recognition system xa tawm cov lus txib blanking, thiab cov neeg hlau tuaj yeem khaws daim ntawv No. 1 thiab muab qhov No. Lub turntable rotates thiab lub angular recognition system pib los txiav txim lub angular txoj hauj lwm. Lub turntable nres thiab angular lees paub ntawm No. 2 daim tiav, thiab cov lus txib blanking raug xa tawm;

5. Cov neeg hlau tau txais cov lus txib blanking ntawm No. 1 ntsug tshuab dhos, txav mus rau qhov chaw thau khoom thiab blanking txoj hauj lwm ntawm No. 1 ntsug tshuab dhos rau cov khoom blanking thiab loading. Tom qab qhov kev txiav txim tiav, lub voj voog ib zaug ntawm lub tshuab dhos ntsug pib;

6. Tus neeg hlau siv cov khoom tiav los ntawm No. 1 ntsug tshuab dhos thiab muab tso rau ntawm No.

7. Cov neeg hlau tau txais cov lus txib blanking ntawm No. 2 ntsug tshuab dhos, txav mus rau qhov chaw thau khoom thiab blanking txoj hauj lwm ntawm No. 2 ntsug tshuab dhos rau cov khoom blanking thiab loading., thiab tom qab ntawd qhov kev txiav txim tiav, thiab lub voj voog ib zaug ntawm ntsug tshuab dhos pib;

8. Tus neeg hlau siv cov khoom tiav los ntawm No. 2 ntsug tshuab dhos thiab muab tso rau ntawm No. 2 txoj hauj lwm ntawm lub workpiece yob-dhau lub rooj;

9. Tus neeg hlau tos rau cov lus txib blanking los ntawm ntsug machining;

10. Vertical machining xa cov lus txib blanking, thiab cov neeg hlau txav mus rau qhov chaw thau khoom thiab blanking txoj haujlwm ntawm ntsug machining, rub thiab txav cov workpieces ntawm No. Cov neeg hlau txav mus rau lub rooj yob-dhau los tuav thiab xa No. 1 thiab No. 2 daim mus rau ntsug machining loading thiab blanking txoj haujlwm raws li, thiab qhov chaw No. Cov neeg hlau txav tawm ntawm qhov kev nyab xeeb ntawm qhov ntsug machining thiab pib ib lub voj voog ua haujlwm;

11. Tus neeg hlau txav mus rau No. 1 loading tray thiab npaj rau kev pib ntawm qhov kev pab cuam thib ob;

Nqe lus piav qhia:

1. Cov neeg hlau yuav siv 16 daim (ib txheej) ntawm lub tais ntim khoom. Tus neeg hlau yuav hloov lub khob nqus dej thiab tso lub phaj faib rau hauv lub pob tawb cia ib ntus;

2. Cov neeg hlau ntim 16 daim (ib txheej) ntawm lub tais blanking. Tus neeg hlau yuav tsum hloov lub khob nqus dej ib zaug, thiab muab cov phaj faib rau ntawm qhov chaw muab faib ntawm qhov chaw ntawm lub pob tawb cia ib ntus;

3. Raws li kev soj ntsuam ntau zaus, xyuas kom tseeb tias tus neeg hlau tso ib feem ntawm cov lus qhia cov qauv;

| 1 | Lub sijhawm machining voj voog | ||||||||||||||

| 2 | Cov neeg siv khoom | Cov khoom siv ua haujlwm | QT450-10-GB/T1348 | Qauv ntawm lub tshuab cuab yeej | Archive No. | ||||||||||

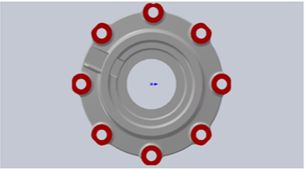

| 3 | Khoom npe | 117 Bearing seat | Daim duab No. | DZ90129320117 | Hnub npaj | 2020.01.04 | Npaj los ntawm | ||||||||

| 4 | Txheej txheem kauj ruam | riam No. | machining cov ntsiab lus | Lub npe cuab yeej | Txiav txoj kab uas hla | Txiav ceev | Kev sib hloov ceev | Pub rau kiv puag ncig | Pub los ntawm lub tshuab cuab yeej | Tus naj npawb ntawm cuttings | Txhua txheej txheem | Lub sijhawm machining | Lub Sijhawm Ua Haujlwm | Plaub-axis tig lub sijhawm | Lub sijhawm hloov cuab yeej |

| 5 | Tsis muaj. | Tsis muaj. | Desoriptions | Cov cuab yeej | D mm | n | R pm | mm/Rev | mm/Min | Sijhawm | mm | Sec | Sec | Sec | |

| 6 |  | ||||||||||||||

| 7 | 1 | T01 | Milling mounting qhov nto | Txoj kab uas hla ntawm 40-lub ntsej muag milling cutter | 40.00 Nws | 180 | 1433 ib | 1.00 Nws | 1433 ib | 8 | 40.0 Nws | 13.40 Nws | 8 | 4 | |

| 8 | Drill DIA 17 mounting qhov | DIA 17 COMBINED DRILL | 17.00 Nws | 100 | Xyoo 1873 | 0.25 | 468 ib | 8 | 32.0 Nws | 32.80 Nws | 8 | 4 | |||

| 9 | T03 | DIA 17 qhov rov qab chamfering | Rov qab chamfering cutter | 16.00 Nws | 150 | 2986 ib | 0.30 Nws | 896 ib | 8 | 30.0 Nws | 16.08 Nws | 16 | 4 | ||

| 10 | Nqe lus piav qhia: | Lub sijhawm txiav: | 62 | Thib ob | Lub sij hawm rau clamping nrog fixture thiab loading thiab blanking cov ntaub ntawv: | 30.00 Nws | Thib ob | ||||||||

| 11 | Lub sijhawm pabcuam: | 44 | Thib ob | Tag nrho machining txiv neej-teev: | 136.27 Nws | Thib ob | |||||||||

| 1 | Lub sijhawm machining voj voog | |||||||||||||||||

| 2 | Cov neeg siv khoom | Cov khoom siv ua haujlwm | QT450-10-GB/T1348 | Qauv ntawm lub tshuab cuab yeej | Archive No. | |||||||||||||

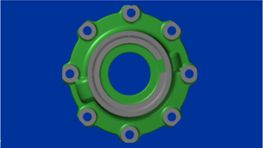

| 3 | Khoom npe | 118 Bearing seat | Daim duab No. | DZ90129320118 | Hnub npaj | 2020.01.04 | Npaj los ntawm | |||||||||||

| 4 | Txheej txheem kauj ruam | riam No. | machining cov ntsiab lus | Lub npe cuab yeej | Txiav txoj kab uas hla | Txiav ceev | Kev sib hloov ceev | Pub rau kiv puag ncig | pub los ntawm tshuab cuab yeej | Tus naj npawb ntawm cuttings | Txhua txheej txheem | Lub sijhawm machining | Lub Sijhawm Ua Haujlwm | Plaub-axis tig lub sijhawm | Lub sijhawm hloov cuab yeej | |||

| 5 | Tsis muaj. | Tsis muaj. | Desoriptions | Cov cuab yeej | D mm | n | R pm | mm/Rev | mm/Min | Sijhawm | mm | Sec | Sec | Sec | ||||

| 6 |

| |||||||||||||||||

| 7 | 1 | T01 | Milling mounting qhov nto | Txoj kab uas hla ntawm 40-lub ntsej muag milling cutter | 40.00 Nws | 180 | 1433 ib | 1.00 Nws | 1433 ib | 8 | 40.0 Nws | 13.40 Nws | 8 | 4 | ||||

| 8 | T02 | Drill DIA 17 mounting qhov | DIA 17 COMBINED DRILL | 17.00 Nws | 100 | Xyoo 1873 | 0.25 | 468 ib | 8 | 32.0 Nws | 32.80 Nws | 8 | 4 | |||||

| 9 | T03 | DIA 17 qhov rov qab chamfering | Rov qab chamfering cutter | 16.00 Nws | 150 | 2986 ib | 0.30 Nws | 896 ib | 8 | 30.0 Nws | 16.08 Nws | 16 | 4 | |||||

| 10 | Nqe lus piav qhia: | Lub sijhawm txiav: | 62 | Thib ob | Lub sij hawm rau clamping nrog fixture thiab loading thiab blanking cov ntaub ntawv: | 30.00 Nws | Thib ob | |||||||||||

| 11 | Lub sijhawm pabcuam: | 44 | Thib ob | Tag nrho machining txiv neej-teev: | 136.27 Nws | Thib ob | ||||||||||||

| 12 | ||||||||||||||||||

Cov cheeb tsam ntawm cov kab ntau lawm

Taw qhia txog cov khoom tseem ceeb ntawm cov kab ntau lawm

Taw qhia txog qhov chaw thau khoom thiab blanking system

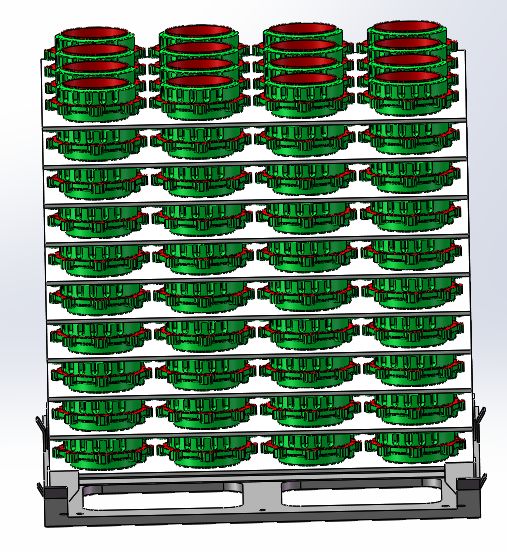

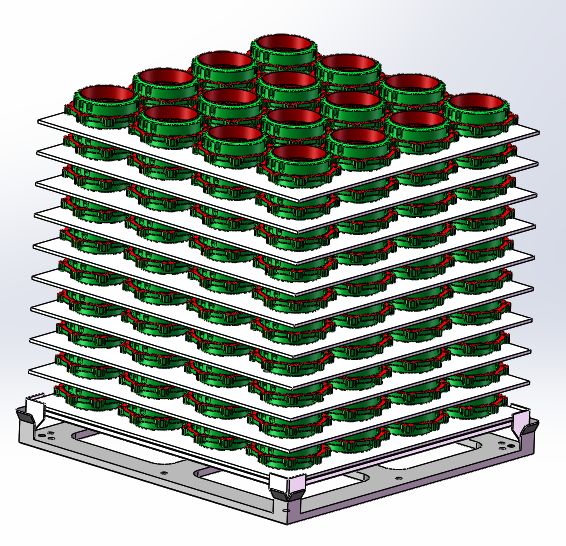

Cov khoom siv cia rau cov kab ntau lawm tsis siv neeg nyob rau hauv cov tswv yim no yog: Lub tais ntim khoom (qhov ntau ntawm cov khoom yuav tsum tau ntim rau ntawm txhua lub tais yuav tsum tau sib tham nrog tus neeg siv khoom), thiab qhov chaw ntawm lub workpiece nyob rau hauv lub tais yuav tsum txiav txim siab tom qab muab 3D kos duab ntawm workpiece dawb paug los yog cov khoom tiag tiag.

1. Cov neeg ua haujlwm ntim cov khoom ua tiav ntawm cov khoom siv (raws li qhia hauv daim duab) thiab forklift lawv mus rau txoj haujlwm;

2. Tom qab hloov lub tais ntawm lub forklift, manually nias lub pob kom paub meej;

3. Tus neeg hlau tuav lub workpiece kom ua tiav cov haujlwm thauj khoom;

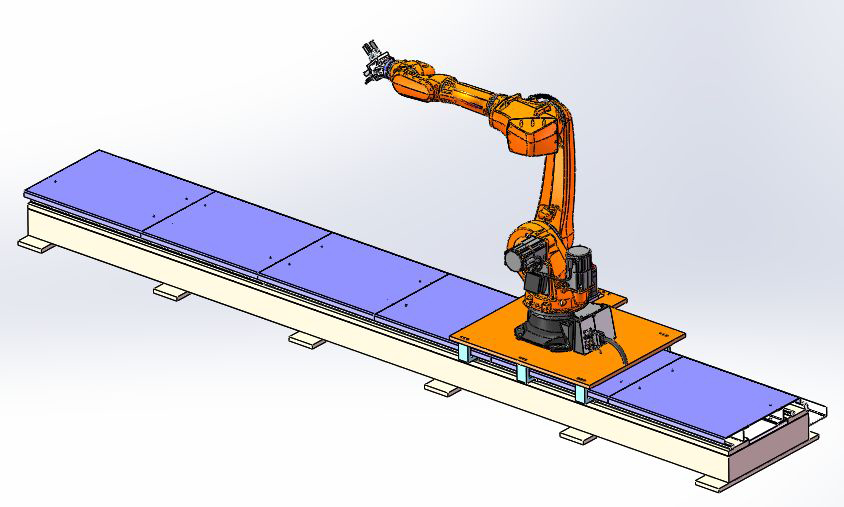

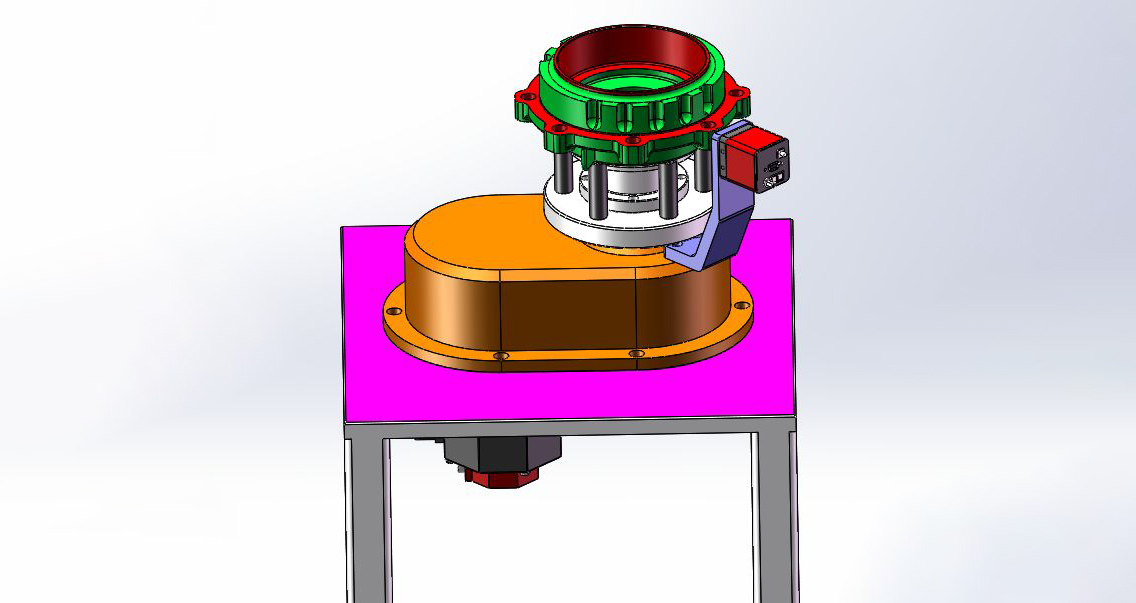

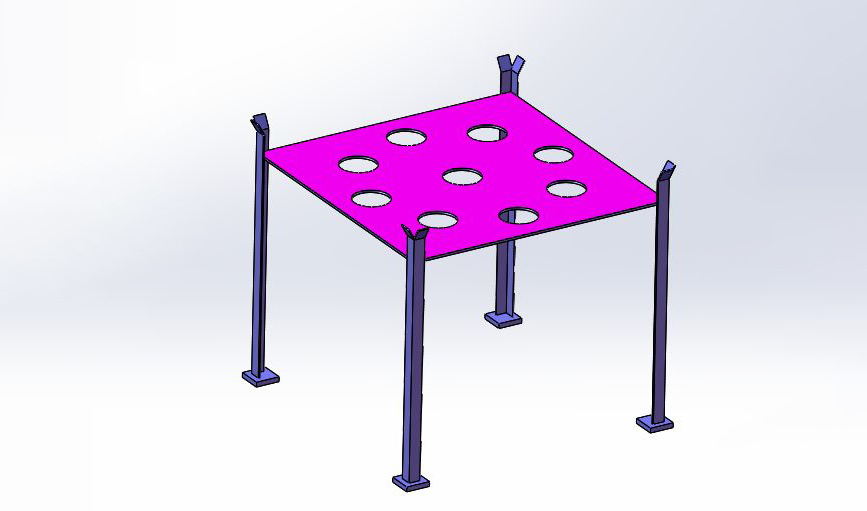

Taw qhia ntawm Robot Travel Axis

Cov qauv yog tsim los ntawm cov neeg hlau sib koom ua ke, lub servo lub cev muaj zog tsav thiab lub pinion thiab khib tsav, kom cov neeg hlau tuaj yeem ua cov lus tsa suab rov qab. Nws paub txog kev ua haujlwm ntawm ib tus neeg hlau ua haujlwm rau ntau yam cuab yeej siv tshuab thiab tuav cov khoom ua haujlwm ntawm ntau qhov chaw nres tsheb thiab tuaj yeem ua kom muaj kev sib koom ua haujlwm ntawm cov neeg hlau sib koom ua ke;

Kev taug kev taug kev siv lub hauv paus welded nrog cov kav hlau thiab yog tsav los ntawm servo lub cev muaj zog, pinion thiab khib tsav, txhawm rau txhim kho kev ua haujlwm ntawm cov neeg hlau sib koom ua ke thiab txhim kho kev siv tus nqi ntawm cov neeg hlau; Txoj kev taug kev yog ntsia rau hauv av;

Chenxuan neeg hlau: SDCX-RB500

| Cov ntaub ntawv yooj yim | |

| Hom | SDCX-RB500 |

| Tus naj npawb ntawm axes | 6 |

| Qhov siab tshaj plaws | 2 101mm |

| Pose repeatability (ISO 9283) | ± 0.05 hli |

| Qhov hnyav | 5 53kg |

| Kev tiv thaiv kev faib tawm ntawm cov neeg hlau | Kev tiv thaiv ntsuas, IP65 / IP67hauv kab dab teg(IEC 60529) |

| Mounting txoj hauj lwm | Qab nthab, tso cai lub kaum sab xis ntawm inclination ≤ 0º |

| Nto tiav, pleev xim | Lub hauv paus ncej: dub (RAL 9005) |

| Ambient kub | |

| Kev ua haujlwm | 283 K txog 328 K (0 ° C txog + 55 ° C) |

| Kev khaws cia thiab kev thauj mus los | 233 K txog 333 K (-40 ° C txog + 60 ° C) |

Nrog rau ntau yam ntawm cov lus tsa suab nyob rau sab nraub qaum thiab hauv qab ntawm tus neeg hlau, ua tus qauv tuaj yeem txuas nrog lub qab nthab nqa. Vim tias qhov dav dav ntawm tus neeg hlau raug txo qis rau qhov txwv, nws tuaj yeem ntsia tau ze rau cov neeg hlau uas nyob ib sab, clamp, lossis workpiece. High-speed txav los ntawm txoj hauj lwm standby mus rau txoj hauj lwm ua hauj lwm thiab ceev ceev txoj hauj lwm thaum lub sij hawm luv luv txav.

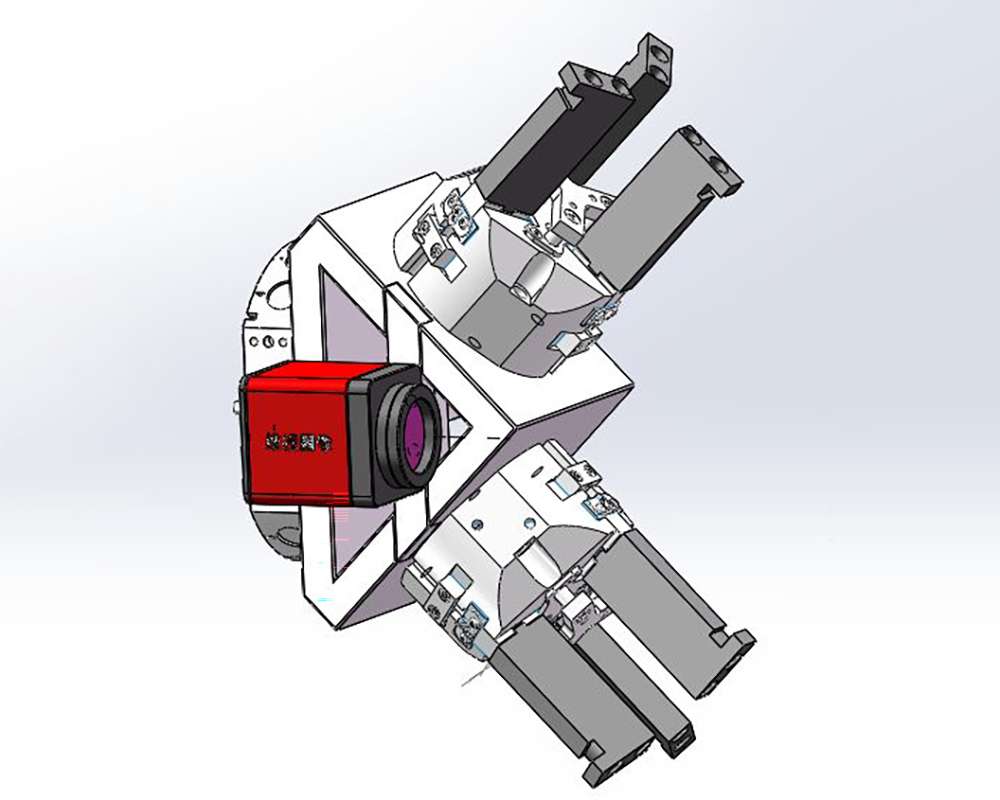

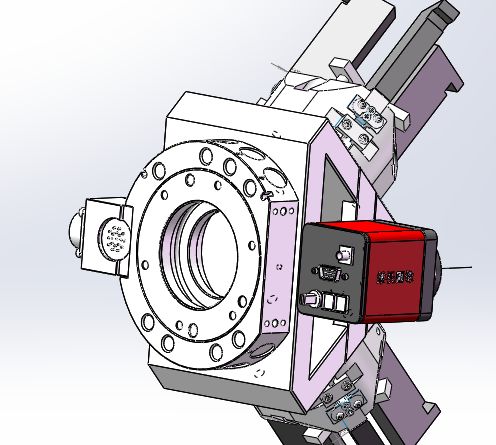

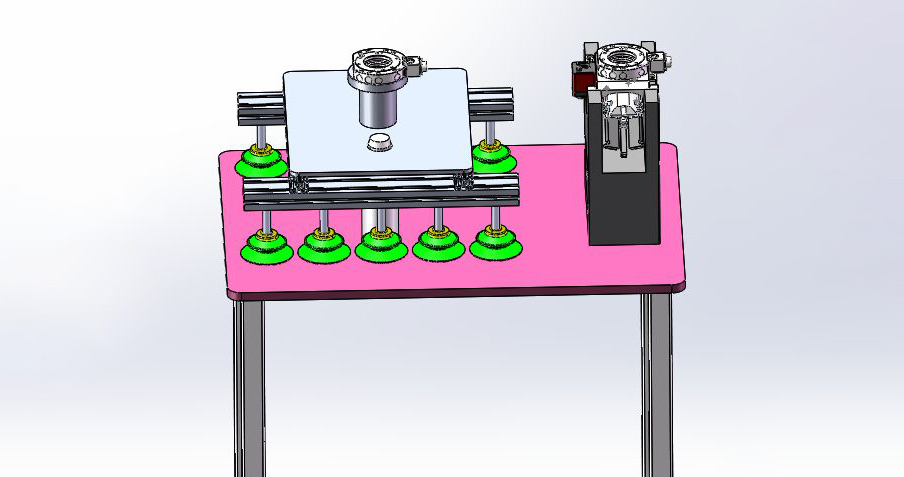

Intelligent neeg hlau loading thiab blanking tong mechanism

Neeg hlau muab faib phaj Tong mechanism

Nqe lus piav qhia:

1. Xav txog cov yam ntxwv ntawm qhov no, peb siv peb-claw sab nraud txhawb nqa txoj kev thauj khoom thiab tsis muaj cov ntaub ntawv, uas tuaj yeem paub ceev tig ntawm cov khoom hauv lub tshuab cuab yeej;

2. Lub tshuab yog nruab nrog txoj haujlwm nrhiav kom pom thiab lub siab ntsuas ntsuas seb qhov clamping li cas thiab qhov siab ntawm qhov chaw yog qhov qub;

3. Lub tshuab yog nruab nrog lub tshuab pressurizer, thiab lub workpiece yuav tsis poob rau hauv ib lub sij hawm luv luv nyob rau hauv cov ntaub ntawv ntawm lub hwj chim tsis ua hauj lwm thiab gas cut-off ntawm lub ntsiab cua Circuit Court;

4. Tes hloov khoom siv tau txais yuav. Hloov lub tshuab ua kom nrawm tuaj yeem ua tiav qhov clamping ntawm cov khoom sib txawv.

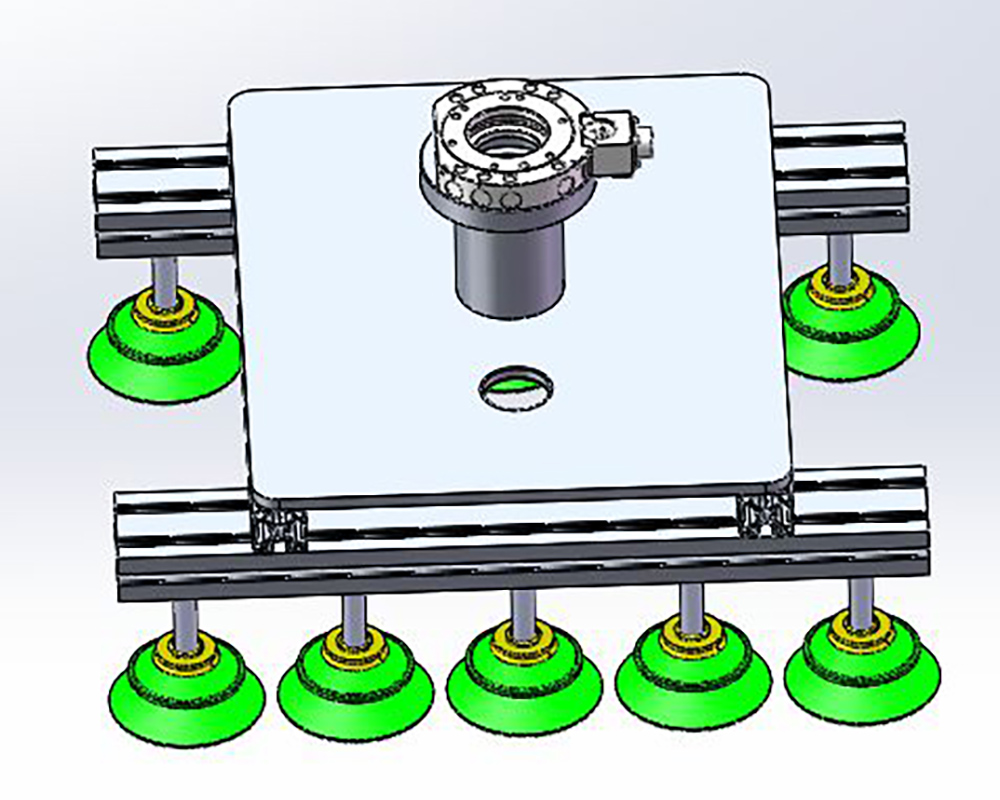

Taw qhia ntawm Tong Hloov Ntaus

Precise tong change device yog siv los hloov cov neeg hlau ceev ceev, cov cuab yeej kawg, thiab lwm yam actuators. Txo cov sij hawm tsis ua haujlwm ntau lawm thiab ua kom cov neeg hlau hloov tau yooj yim, muaj xws li:

1. Xauv thiab zawm huab cua siab;

2. Ntau lub zog, kua thiab roj modules tuaj yeem siv tau;

3. Cov txheej txheem kev teeb tsa tuaj yeem txuas nrog lub tshuab cua sai sai;

4. Cov chaw tuav pov hwm tshwj xeeb tuaj yeem tiv thaiv qhov kev pheej hmoo ntawm kev txiav tawm roj;

5. Tsis muaj lub caij nplooj ntoos hlav tawm dag zog; 6. Muaj feem xyuam rau automation teb;

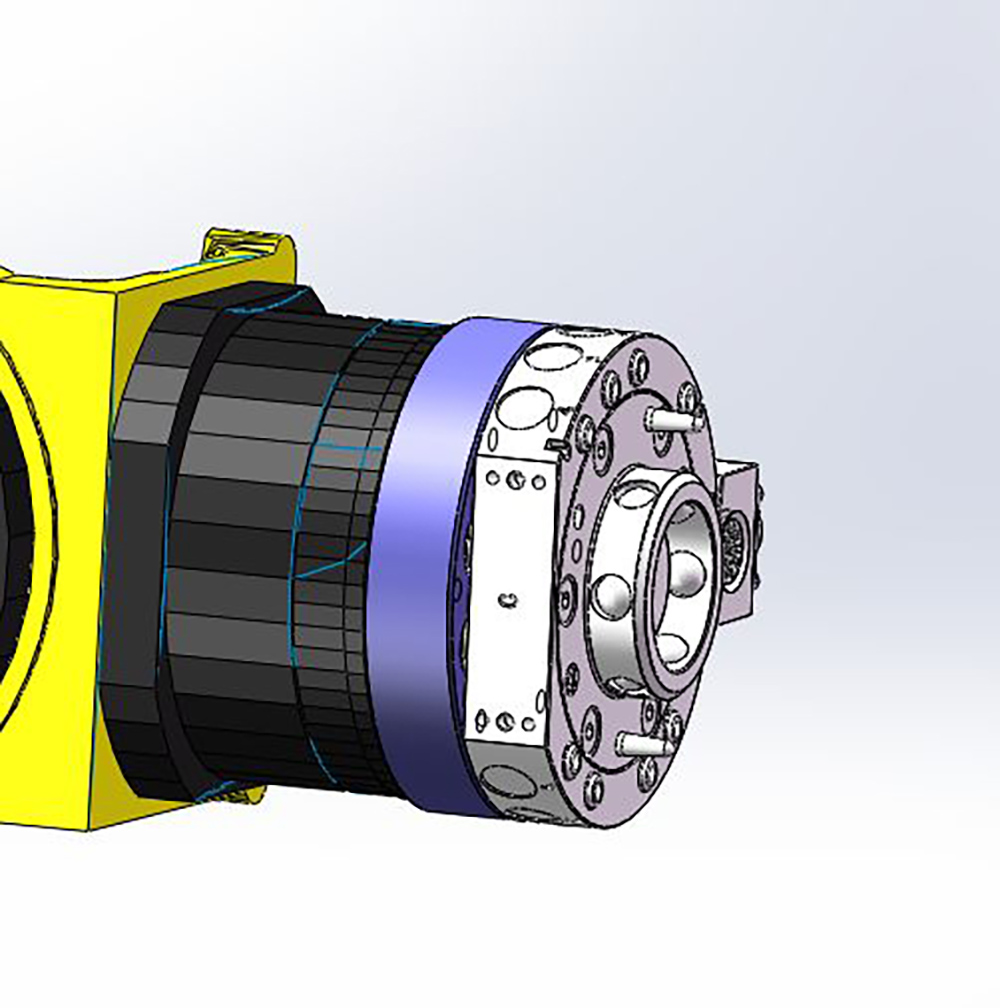

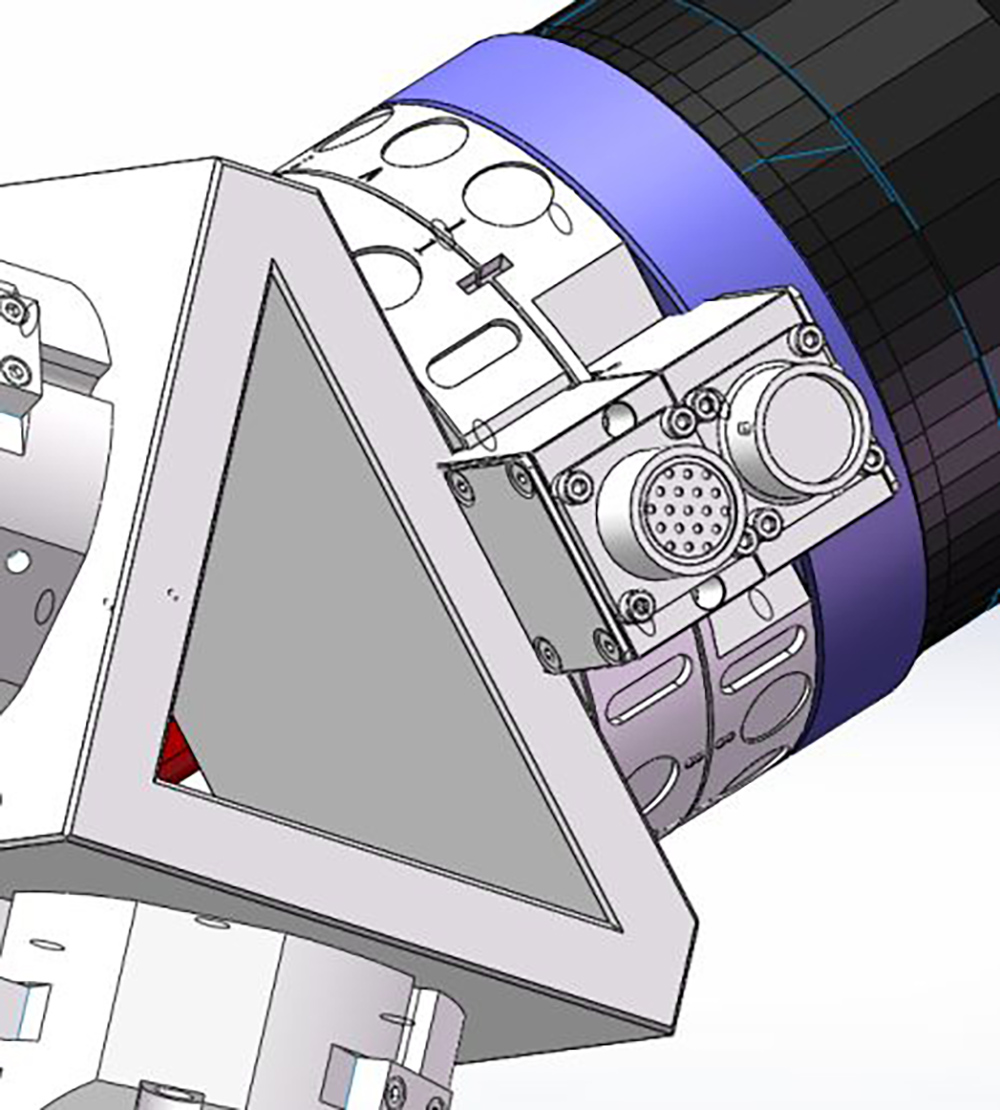

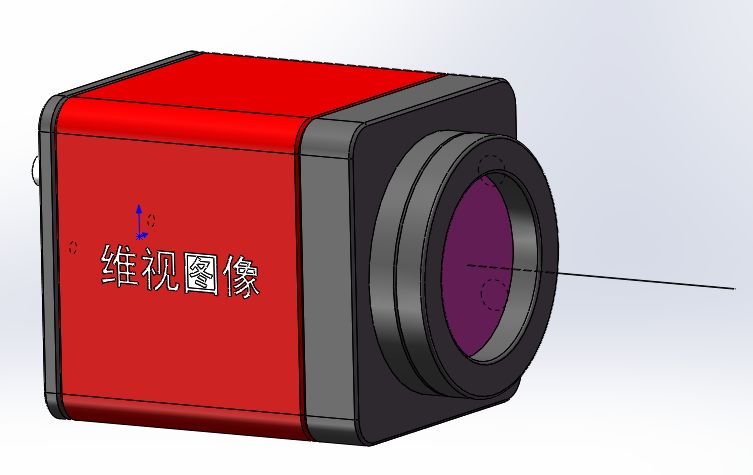

Taw qhia rau Lub Zeem Muag System-Industrial Lub Koob Yees Duab

1. Lub koob yees duab tau txais cov khoom zoo CCD thiab CMDS chips, uas muaj cov yam ntxwv ntawm cov kev daws teeb meem siab, siab rhiab heev, siab teeb liab-rau-frequency piv, dav dynamic ntau, zoo heev imaging zoo thiab thawj-chav kawm ntawv muaj peev xwm kho xim;

2. Lub koob yees duab hauv cheeb tsam muaj ob hom kev sib kis: GIGAbit Ethernet (GigE) interface thiab USB3.0 interface;

3. Lub koob yees duab muaj cov qauv compact, me me tsos, hnav thiab ntsia. Kev sib kis ceev ceev, muaj peev xwm tiv thaiv kev cuam tshuam, ruaj khov ntawm cov duab zoo; Nws muaj feem xyuam rau kev nyeem ntawv code, kuaj pom qhov tsis xws luag, DCR thiab paub cov qauv; Lub koob yees duab xim muaj peev xwm kho xim muaj zog, haum rau cov xwm txheej uas yuav tsum tau muaj xim siab;

Taw qhia ntawm Angular Automatic Recognition System

Muaj nuj nqi Taw qhia

1. Cov neeg hlau clamps lub workpieces los ntawm cov pob tawb thauj khoom thiab xa mus rau qhov chaw ntawm lub turntable;

2. Turntable rotates nyob rau hauv lub tsav ntawm servo lub cev muaj zog;

3. Lub teeb pom kev zoo (lub koob yees duab kev lag luam) ua haujlwm txhawm rau txheeb xyuas txoj haujlwm angular, thiab lub turntable nres los txiav txim siab txoj haujlwm angular;

4. Tus neeg hlau tshem tawm cov khoom ua haujlwm thiab muab lwm daim rau hauv kev txheeb xyuas lub kaum ntse ntse;

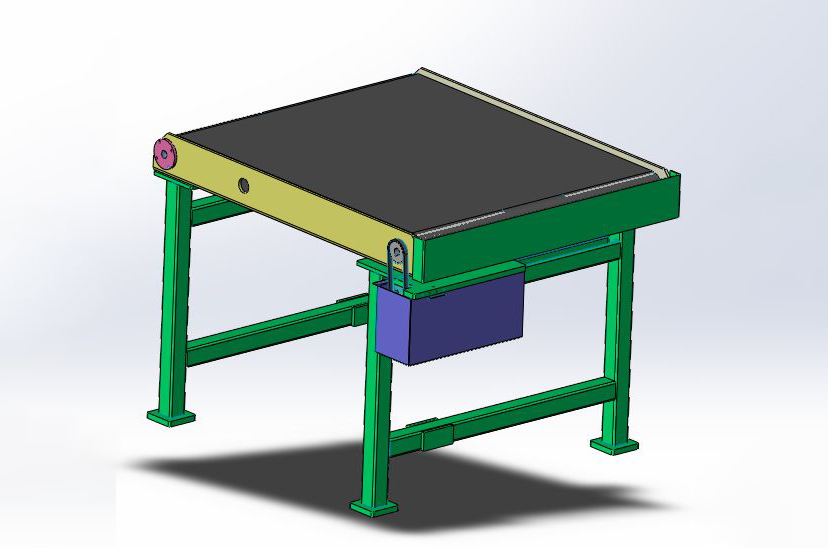

Taw qhia rau Workpiece Roll-over Table

Roll-over station:

1. Tus neeg hlau siv lub workpiece thiab muab tso rau ntawm qhov chaw nyob ntawm lub rooj dov (qhov chaw nres tsheb sab laug hauv daim duab);

2. Tus neeg hlau tuav lub workpiece los ntawm saum toj no kom paub txog lub rollover ntawm lub workpiece;

Robot Tong qhov rooj

Muaj nuj nqi Taw qhia

1. Tom qab txhua txheej ntawm cov khoom raug thauj khoom, cov txheej txheem muab faib yuav tsum muab tso rau hauv lub pob tawb khaws cia ib ntus rau cov phaj faib;

2. Cov neeg hlau tuaj yeem hloov tau sai nrog lub tshuab nqus tsev twj los ntawm lub tshuab hloov pauv thiab tshem tawm cov phaj sib faib;

3. Tom qab cov ntawv muab faib tau zoo, tshem tawm lub khob nqus dej thiab hloov nrog lub pneumatic tong mus txuas ntxiv nrog cov khoom thauj khoom thiab blanking;

Basket rau ib ntus cia ntawm cov phaj faib

Muaj nuj nqi Taw qhia

1. Lub pob tawb ib ntus rau kev faib cov phaj yog tsim thiab npaj raws li cov phaj faib rau kev thauj khoom yog muab tshem tawm ua ntej thiab cov phaj muab faib rau blanking yog siv tom qab;

2. Lub chaw thau khoom muab faib cov phaj yog muab tso rau hauv manually thiab tsis zoo sib xws. Tom qab muab faib phaj rau hauv lub pob tawb khaws cia ib ntus, tus neeg hlau tuaj yeem tshem tawm thiab tso nws kom huv si;

Phau ntawv sampling rooj

Nqe lus piav qhia:

1. Teem caij sib txawv ntawm phau ntawv random sampling zaus rau cov theem ntau lawm, uas tuaj yeem tswj xyuas qhov ua tau zoo ntawm kev ntsuas hauv online;

2. Cov lus qhia rau kev siv: Lub manipulator yuav muab lub workpiece mus rau lub teeb nyob rau hauv lub sampling lub rooj raws li lub zaus teem manually, thiab sai li sai tau nrog lub teeb liab. Tus neeg soj ntsuam yuav nias lub pob kom thauj cov khoom ua haujlwm mus rau qhov chaw nyab xeeb sab nraum qhov kev tiv thaiv, tshem tawm cov khoom ua haujlwm rau kev ntsuas thiab khaws cia cais tom qab ntsuas;

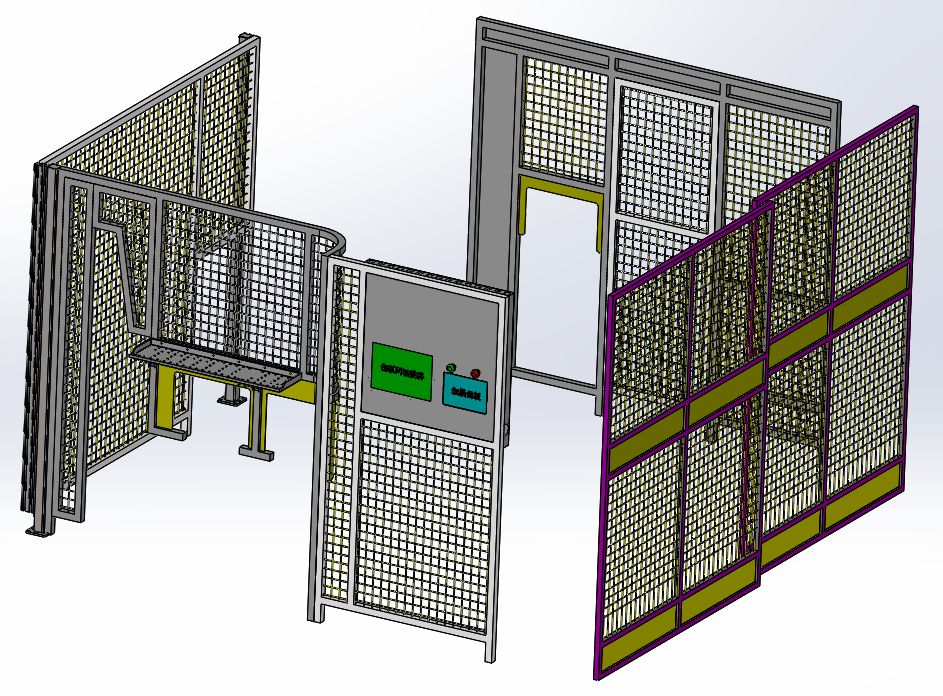

Cov khoom tiv thaiv

Nws yog tsim los ntawm lub teeb yuag aluminium profile (40 × 40) + mesh (50 × 50), thiab lub vijtsam kov thiab khawm nres thaum muaj xwm ceev tuaj yeem ua ke rau hauv cov khoom tiv thaiv, kev sib koom ua ke kev nyab xeeb thiab kev zoo nkauj.

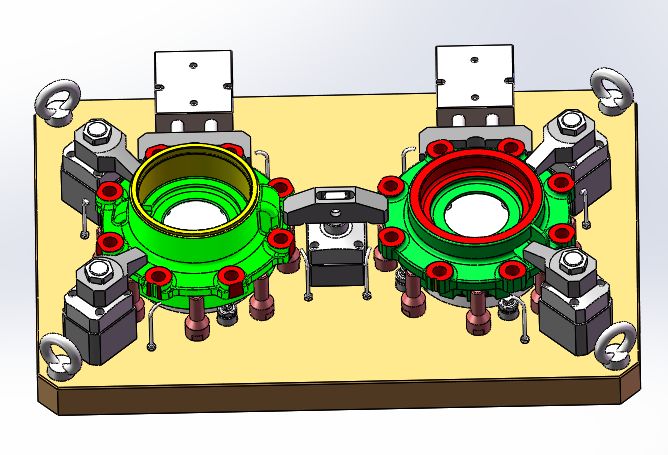

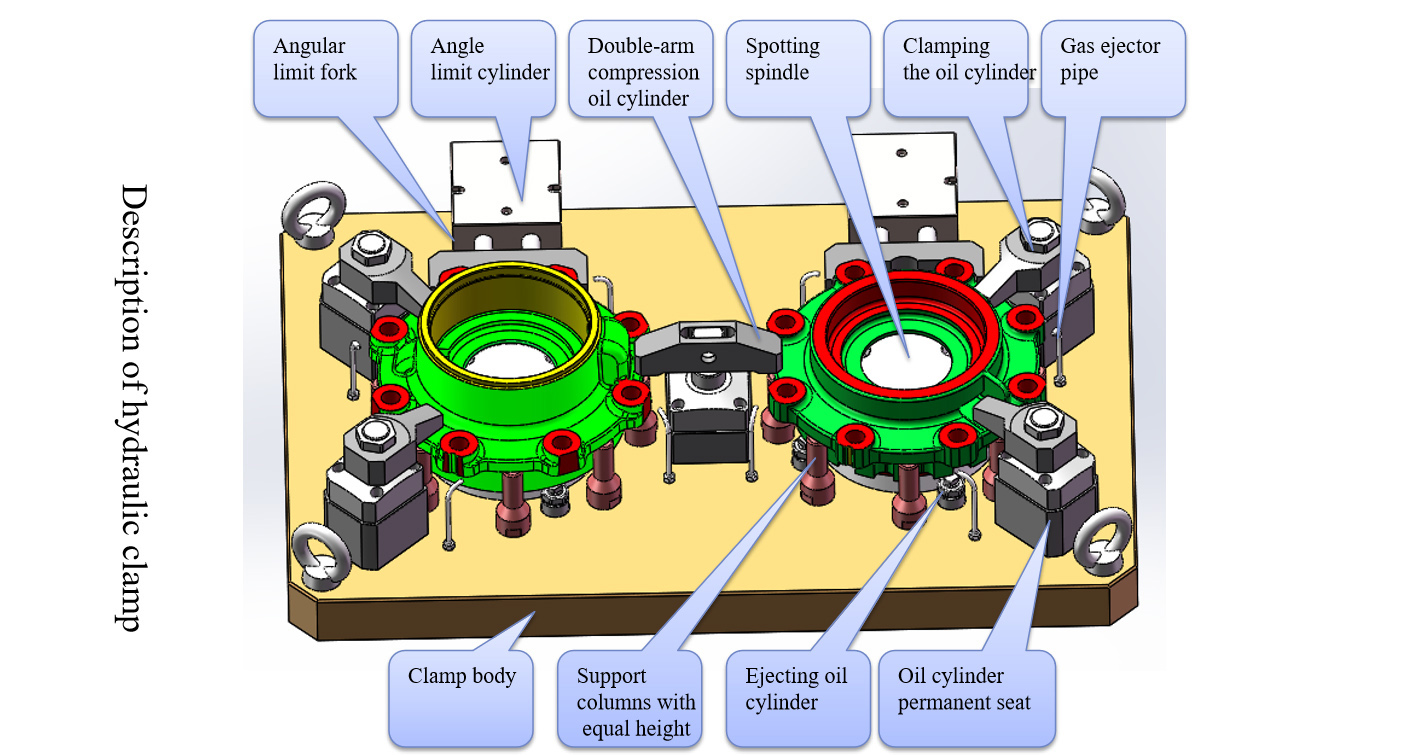

Taw qhia ntawm OP20 Hydraulic Fixture

Cov lus qhia ua:

1. Siv lub φ165 puab bore raws li lub hauv paus qhov, coj D datum raws li lub hauv paus dav hlau, thiab coj lub sab arc ntawm tus thawj coj ntawm ob mounting qhov raws li lub angular txwv;

2. Tswj lub loosening thiab nias qhov kev txiav txim ntawm lub phaj nias los ntawm cov lus txib ntawm lub tshuab cuab tam M kom tiav cov chamfering ua tiav ntawm lub dav hlau sab sauv ntawm mounting qhov tus thawj coj, 8-φ17 mounting qhov thiab ob qhov kawg ntawm lub qhov;

3. Lub fixture muaj lub luag hauj lwm ntawm positioning, tsis siv neeg clamping, huab cua ceev nrhiav kom tau, tsis siv neeg loosening, tsis siv neeg ejection, tsis siv neeg nti flushing thiab tsis siv neeg tu ntawm positioning datum dav hlau;

Cov Khoom Siv Khoom Siv rau Cov Kab Ntau Lawm

1. Cov kab ntau lawm cov khoom siv clamp muaj lub luag haujlwm ntawm tsis siv neeg clamping thiab loosening, thiab paub tias tsis siv neeg clamping thiab loosening functions nyob rau hauv kev tswj ntawm lub teeb liab ntawm lub manipulator system koom tes nrog kev thauj khoom thiab blanking kev txiav txim;

2. Lub skylight txoj hauj lwm los yog tsis siv neeg lub qhov rooj module yuav tsum tau tshwj tseg rau cov hlau phaj ntawm cov khoom kab ntau lawm, los koom tes nrog cov hluav taws xob tswj teeb liab thiab manipulator kev sib txuas lus ntawm peb lub tuam txhab;

3. Cov khoom siv kab ntau lawm muaj kev sib txuas lus nrog tus neeg siv los ntawm kev sib txuas ntawm cov khoom hnyav-load connector (los yog aviation plug);

4. Cov khoom siv kab ntau lawm muaj qhov chaw sab hauv (kev cuam tshuam) loj dua qhov kev nyab xeeb ntawm kev tswj lub puab tsaig;

5. Cov khoom siv kab ntau lawm yuav tsum xyuas kom meej tias tsis muaj cov hlau nplaum seem ntawm qhov chaw ntawm qhov clamp. Yog tias tsim nyog, cua tshuab yuav tsum tau nce ntxiv rau kev ntxuav (lub chuck yuav tsum tig thaum ntxuav);

6. Cov khoom siv kab ntau lawm muaj cov nti tawg zoo. Yog hais tias tsim nyog, lub auxiliary high-pressure chip breaking device ntawm peb lub tuam txhab yuav tsum tau ntxiv;

7. Thaum cov khoom siv kab ntau lawm yuav tsum tau nres ntawm lub tshuab cuab tam spindle, ntxiv cov haujlwm no thiab muab cov cim hluav taws xob sib thooj;

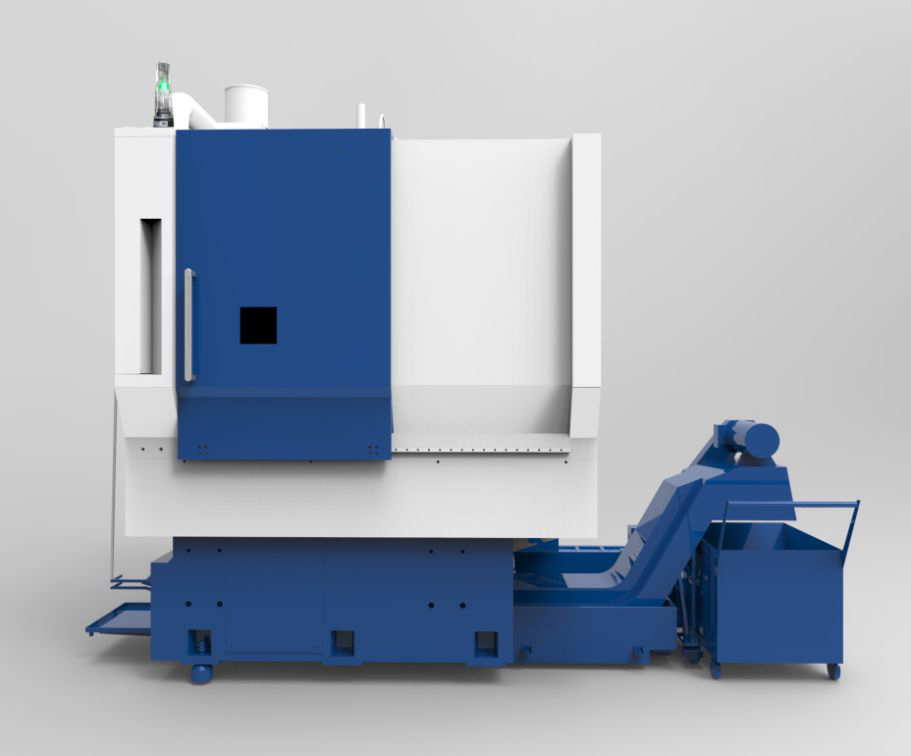

Taw qhia ntawm Vertical Lathe VTC-W9035

VTC-W9035 NC ntsug tshuab dhos yog tsim nyog rau machining rotating qhov chaw xws li iav blanks, flanges thiab tshwj xeeb-zoo li tus plhaub, tshwj xeeb tshaj yog haum rau leej, zog-txuag thiab npaum tig ntawm qhov chaw xws li disks, hubs, nres discs, twj tso kua mis lub cev, valve lub cev thiab plhaub. Lub tshuab cuab yeej muaj qhov zoo ntawm qhov zoo tag nrho rigidity, siab precision, loj tshem tawm tus nqi ntawm cov hlau ib chav tsev lub sij hawm, zoo raug tuav, muaj kev ntseeg siab, yooj yim txij nkawm, thiab ntau yam kev siv. Kab ntau lawm, kev ua haujlwm siab thiab tus nqi qis.

| Hom qauv | VTC-W9035 |

| Qhov siab tshaj plaws txoj kab uas hla ntawm lub txaj lub cev | Φ900 hli |

| Maximum tig txoj kab uas hla ntawm zawv zawg phaj | Φ590 hli |

| Qhov siab tshaj txoj kab uas hla ntawm workpiece | Φ850 hli |

| Maximum tig ntev ntawm workpiece | 700 hli |

| Ceev ntau ntawm spindle | 20-900 r / min |

| Qhov system | FANUC 0i - TF |

| Qhov siab tshaj plaws stroke ntawm X / Z axis | 600/800 hli |

| Kev txav ceev ceev ntawm X / Z axis | 20/20 m / min |

| Ntev, dav thiab qhov siab ntawm lub tshuab cuab yeej | 3550 * 2200 * 3950 hli |

| Tej yaam num | Chav tsev | Parameter | |

| Kev ua ntau yam | X axis taug kev | mm | 1100 |

| X axis taug kev | mm | 610 | |

| X axis taug kev | mm | 610 | |

| Qhov deb ntawm lub qhov ntswg spindle mus rau qhov chaw ua haujlwm | mm | 150-760 Nws | |

| Workbench | Qhov loj ntawm workbench | mm | 1200 × 600 hli |

| Max load ntawm workbench | kg | 1000 | |

| T-groove (loj × qhov ntau × qhov sib nrug) | mm | 18 × 5 × 100 hli | |

| Pub | Ceev ceev ceev ntawm X / Y / Z axis | m/min | 36/36/24 ib |

| Spindle | Tsav tsheb hom | Siv hom | |

| Spindle taper | BT40 | ||

| Kev khiav hauj lwm ceev tshaj plaws | r / min | 8000 | |

| Hwj chim (Rated / Maximum) | KW | 11/18.5 Nws | |

| Torque (Rated / Maximum) | N·m | 52.5/118 | |

| Qhov tseeb | X / Y / Z axis positioning raug (ib nrab kaw voj) | mm | 0.008 (tag nrho ntev) |

| X / Y / Z axis repetition raug (ib nrab kaw voj) | mm | 0.005 (tag nrho ntev) | |

| Tool magazine | Hom | Disc | |

| Cov cuab yeej magazine muaj peev xwm | 24 | ||

| Cov cuab yeej loj tshaj plaws(Tag nrho cov cuab yeej txoj kab uas hla / qhov khoob uas nyob ib sab lub cuab tam txoj kab uas hla / ntev) | mm | Φ78/Φ150/300 | |

| Qhov siab tshaj plaws qhov hnyav | kg | 8 | |

| Lwm yam | Cua muab siab | MPa | 0.65 ib |

| Muaj peev xwm | KVA | 25 | |

| Zuag qhia tag nrho qhov ntev ntawm lub tshuab cuab yeej (ntev × dav × qhov siab) | mm | 2900 × 2800 × 3200 hli | |

| Qhov hnyav ntawm lub tshuab cuab yeej | kg | 7000 | |