Txheej Txheem Kev Ntsuam Xyuas Kab Ntau Lawm

Tuag retrorei kuv technischen prozess

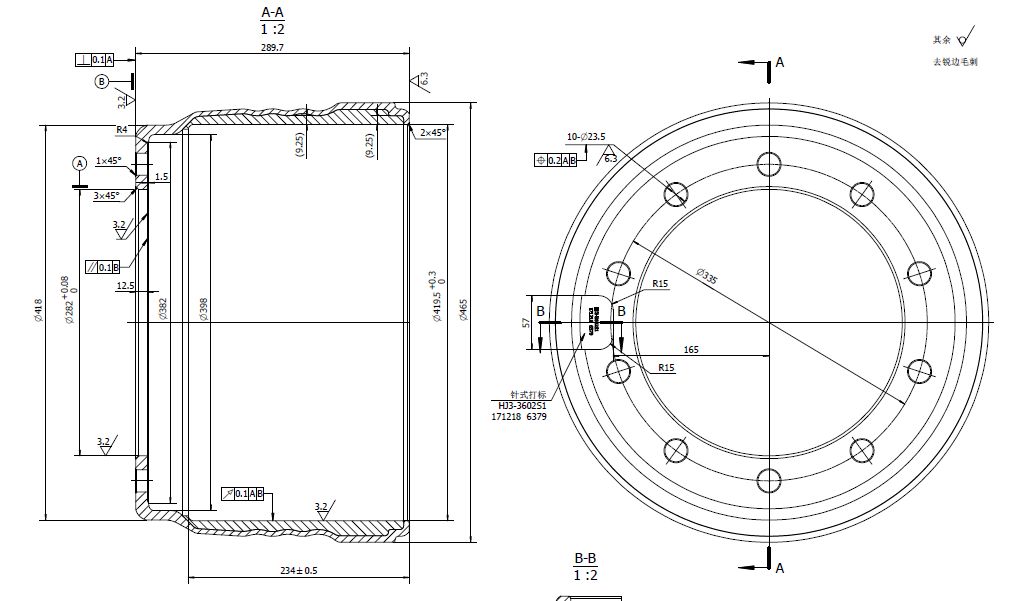

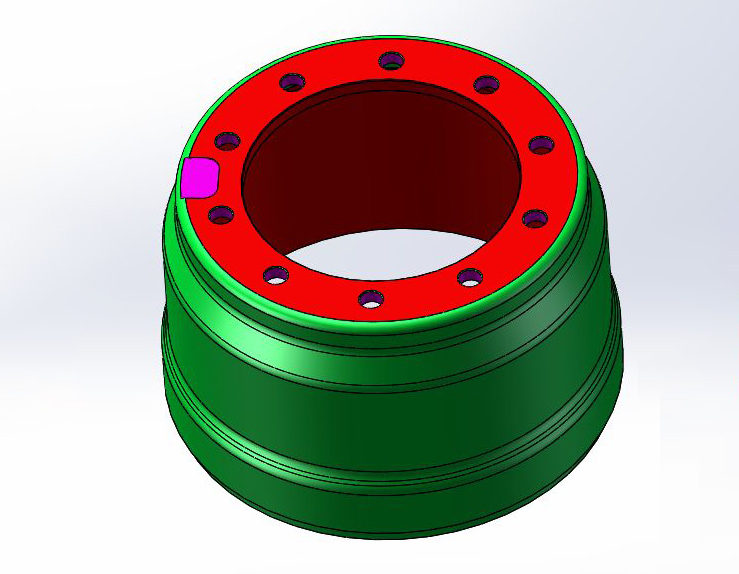

1. Cov txheej txheem clamping pov tseg yog saws thaum tig. Tig tag nrho cov machining qhov chaw, suav nrog hauv qab ntawm lub workpieces.

2. Thaum lub sij hawm drilling, hydraulic clamps yuav tsum tau siv nyob rau hauv lub puab txoj kab uas hla ntawm Φ282 thiab lub Upper kawg lub ntsej muag, laum 10-Φ23.5 mounting qhov thiab chamfering ntawm ob sab, thiab zeb pneumatic marking cheeb tsam;

Cov npe khoom siv

| OP10 machining Cycle timer | |||||||||||||||

| Kev piav qhia |

| ||||||||||||||

| Cov neeg siv khoom | Cov khoom siv ua haujlwm | 45 | Qauv ntawm lub tshuab cuab yeej | Archive No. | |||||||||||

| Khoom npe | Txiav cov cuab yeej ncej welded qhov chaw | Daim duab No. | Hnub npaj | 2021.1.19 | Npaj los ntawm | ||||||||||

| Txheej txheem kauj ruam | riam No. | machining cov ntsiab lus | Lub npe cuab yeej | Txiav txoj kab uas hla | Txiav ceev | Kev sib hloov ceev | Pub rau kiv puag ncig | pub los ntawm tshuab cuab yeej | Tus naj npawb ntawm cuttings | Txhua txheej txheem | Lub sijhawm machining | Lub Sijhawm Ua Haujlwm | Tighten thiab loosen | Lub sijhawm hloov cuab yeej | |

| Tsis muaj. | Tsis muaj. | Desoriptions | Cov cuab yeej | D mm | VcM/min | R pm | mm/Rev | mm/Min | Sijhawm | Ntev mm | Sec | Sec | Sec | ||

| 1 | T01 | Lathe lub ntsej muag sab sauv roughly | 455.00 Nws | 450 | 315 | 0.35 Nws | 110 | 1 | 20.0 Nws | 10.89 Nws | 3 | 3 | |||

| 2 | T02 | Tshuab dhos roughly DIA 419.5 puab bore, DIA 382 kauj ruam lub ntsej muag thiab DIA 282 puab bore | 419.00 Nws | 450 | 342 ib | 0.35 Nws | 120 | 1 | 300.0 Nws | 150.36 Nws | 3 | 3 | |||

| 3 | T03 | Lathe kawg lub ntsej muag precisely | 455.00 Nws | 450 | 315 | 0.25 | 79 | 1 | 20.0 Nws | 15.24 Nws | 3 | ||||

| 4 | T04 | Tshuab dhos precisely lub DIA 419.5 puab bore, DIA 382 kauj ruam lub ntsej muag thiab DIA 282 puab bore | 369.00 Nws | 450 | 388 | 0.25 | 97 | 1 | 300.0 Nws | 185.39 Nws | |||||

| 5 | T05 | Lathe rov qab thiab roughly lub ntsej muag qis kawg | 390.00 Nws | 420 | 343 | 0.35 Nws | 120 | 1 | 65.0 ua | 32.49 Nws | 3 | ||||

| 6 | T06 | Lathe thim rov qab thiab precisely lub ntsej muag qis kawg | 390.00 Nws | 450 | 367 ib | 0.25 | 92 | 1 | 65.0 ua | 42.45 Nws | 3 | ||||

| Nqe lus piav qhia: | Lub sijhawm txiav: | 437 ib | Thib ob | Lub sij hawm rau clamping nrog fixture thiab loading thiab blanking cov ntaub ntawv: | 15.00 Nws | Thib ob | |||||||||

| Lub sijhawm pabcuam: | 21 | Thib ob | Tag nrho machining txiv neej-teev: | 472.81 ib | Thib ob | ||||||||||

| OP20 machining Cycle timer | |||||||||||||||

| Kev piav qhia |  | ||||||||||||||

| Cov neeg siv khoom | Cov khoom siv ua haujlwm | HT 250 | Qauv ntawm lub tshuab cuab yeej | Archive No. | |||||||||||

| Khoom npe | Nres nruas | Daim duab No. | Hnub npaj | 2021.1.19 | Npaj los ntawm | ||||||||||

| Txheej txheem kauj ruam | riam No. | machining cov ntsiab lus | Lub npe cuab yeej | Txiav txoj kab uas hla | Txiav ceev | Kev sib hloov ceev | Pub rau kiv puag ncig | pub los ntawm tshuab cuab yeej | Tus naj npawb ntawm cuttings | Txhua txheej txheem | Lub sijhawm machining | Lub Sijhawm Ua Haujlwm | Tighten thiab loosen | Lub sijhawm hloov cuab yeej | |

| Tsis muaj. | Tsis muaj. | Desoriptions | Cov cuab yeej | D mm | VcM/min | R pm | mm/Rev | mm/Min | Sijhawm | Ntev mm | Sec | Sec | Sec | ||

| 1 | T01 | Laum 10-DIA 23.5 mounting qhov | Down-the-qhov laum DIA 23.5 | 23.50 Nws | 150 | 20 33 | 0.15 | 305 | 10 | 15.0 Nws | 29.52 Nws | 20 | 5 | ||

| 2 | T04 | 10-DIA 23 Orifice Chamfering | DIA 30 compound reaming chamfering cutter | 30.00 Nws | 150 | 1592 ib | 0.20 ib | 318 | 10 | 3.0 | 6.65 ib | 20 | 5 | ||

| 3 | T06 | 10-DIA 23.5 Back orifice chamfering | DIA 22 rov qab chamfering cutter | 22.00 Nws | 150 | 2171 ib | 0.20 ib | 434 ib | 10 | 3.0 | 4.14 ib | 40 | 5 | ||

| 4 | T08 | Milling Marking Area | DIA 30 square xub pwg milling | 30.00 Nws | 80 | 849 ib | 0.15 | 127 | 1 | 90.0 ua | 42.39 Nws | 4 | 5 | ||

| Nqe lus piav qhia: | Lub sijhawm txiav: | 82 | Thib ob | Lub sij hawm rau clamping nrog fixture thiab loading thiab blanking cov ntaub ntawv: | 30 | Thib ob | |||||||||

| Lub sijhawm pabcuam: | 104 | Thib ob | Tag nrho machining txiv neej-teev: | 233.00 Nws | Thib ob | ||||||||||

Taw qhia rau Kab Ntau Lawm

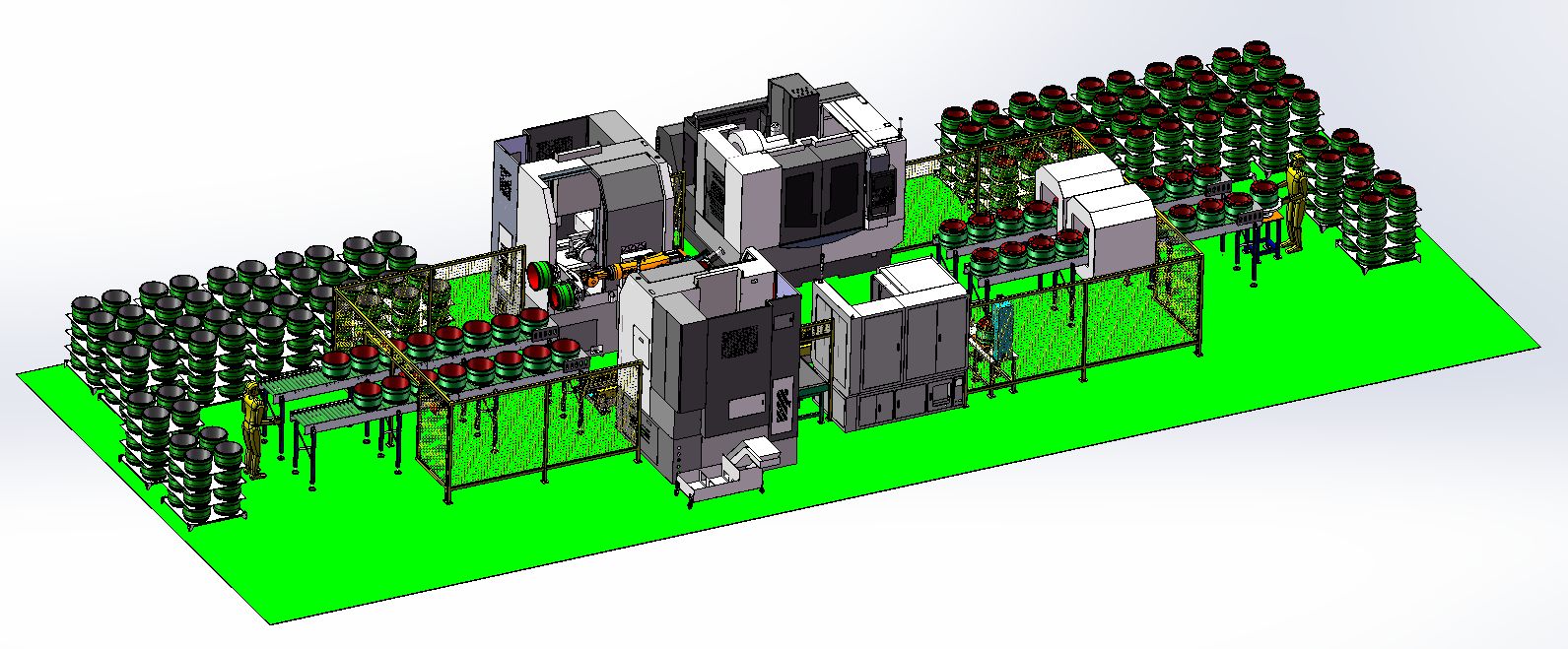

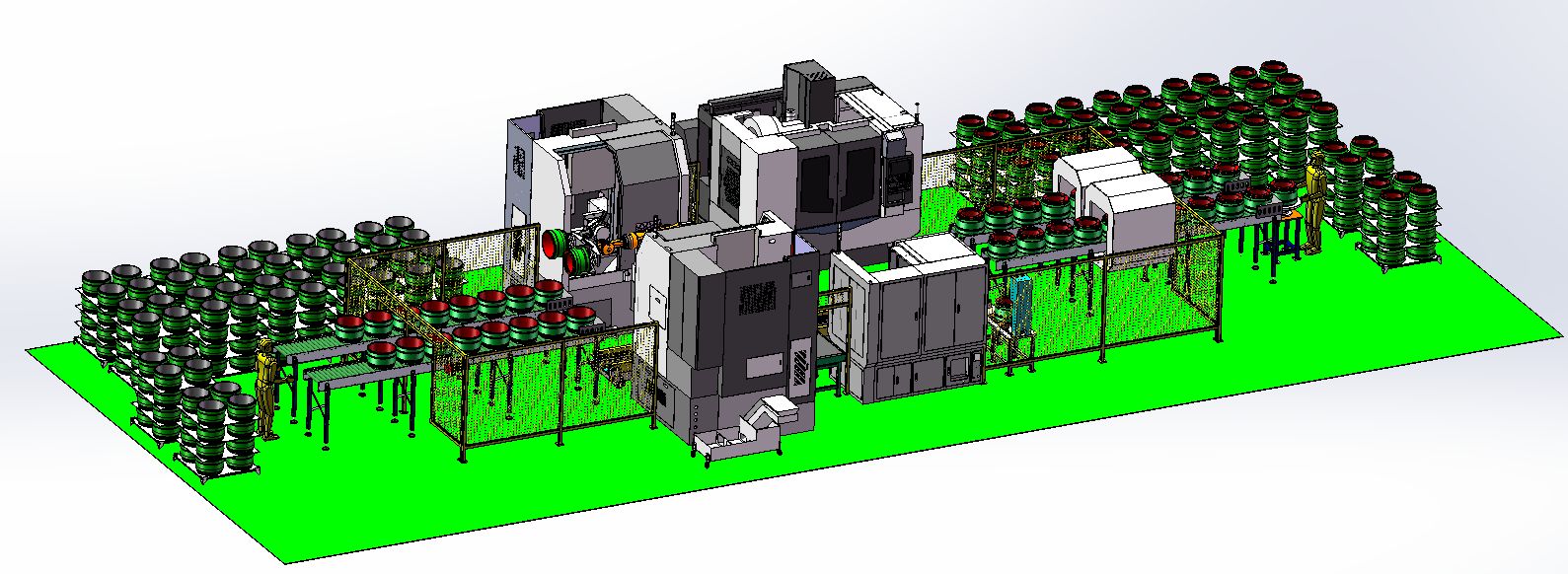

Layout ntawm Kab Ntau Lawm

Taw qhia rau Kab Ntau Lawm

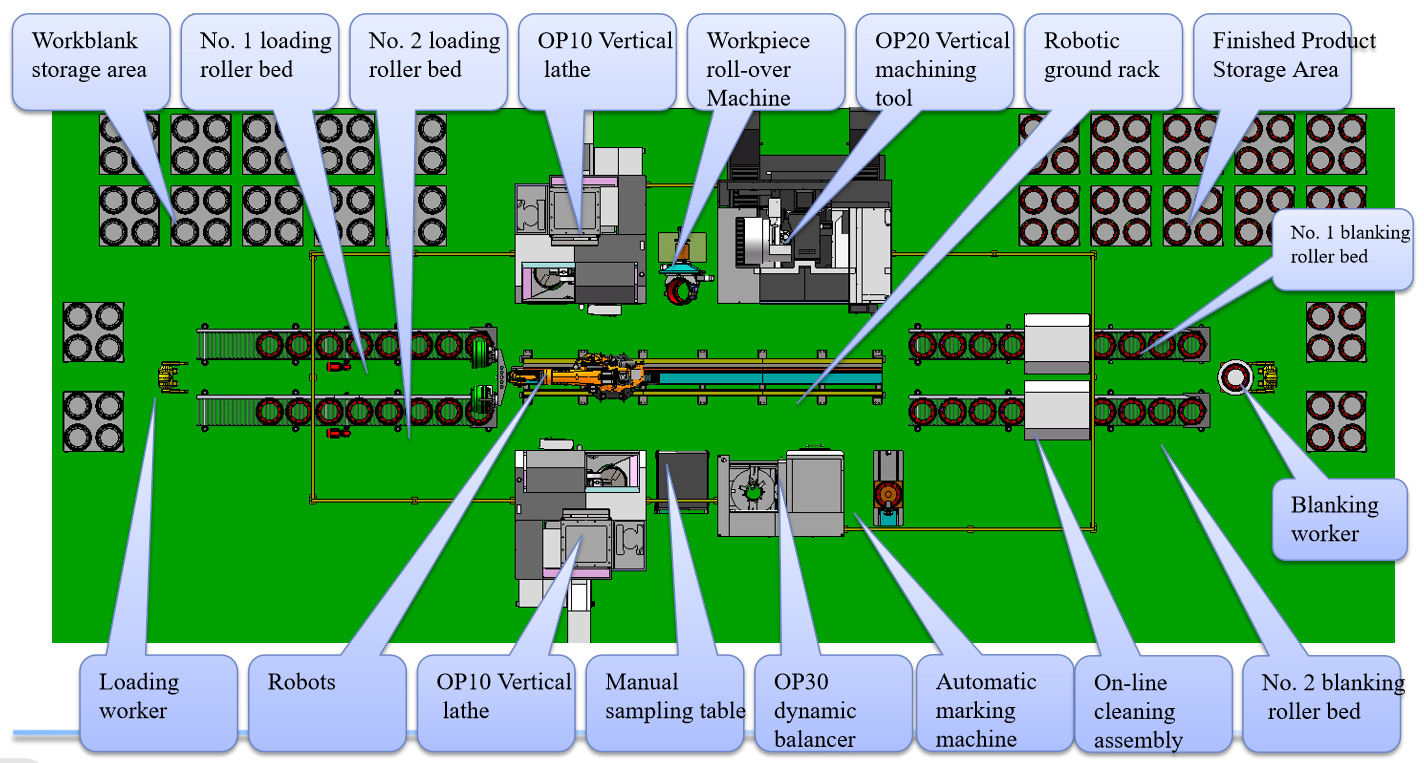

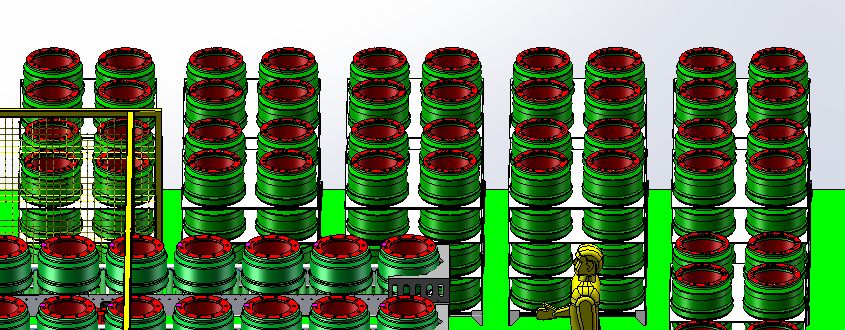

Cov kab ntau lawm muaj xws li 1 chaw thau khoom, 1 tshuab dhos machining chav tsev thiab 1 blanking unit. Cov neeg hlau thauj khoom ntawm cov chaw nres tsheb hauv txhua chav. Forklifts tso cov pob tawb nyob rau hauv pem hauv ntej ntawm cov chaw thau khoom thiab blanking units; Cov kab ntau lawm npog thaj tsam ntawm: 22.5m × 9m

Kev piav qhia ntawm cov kab ntau lawm

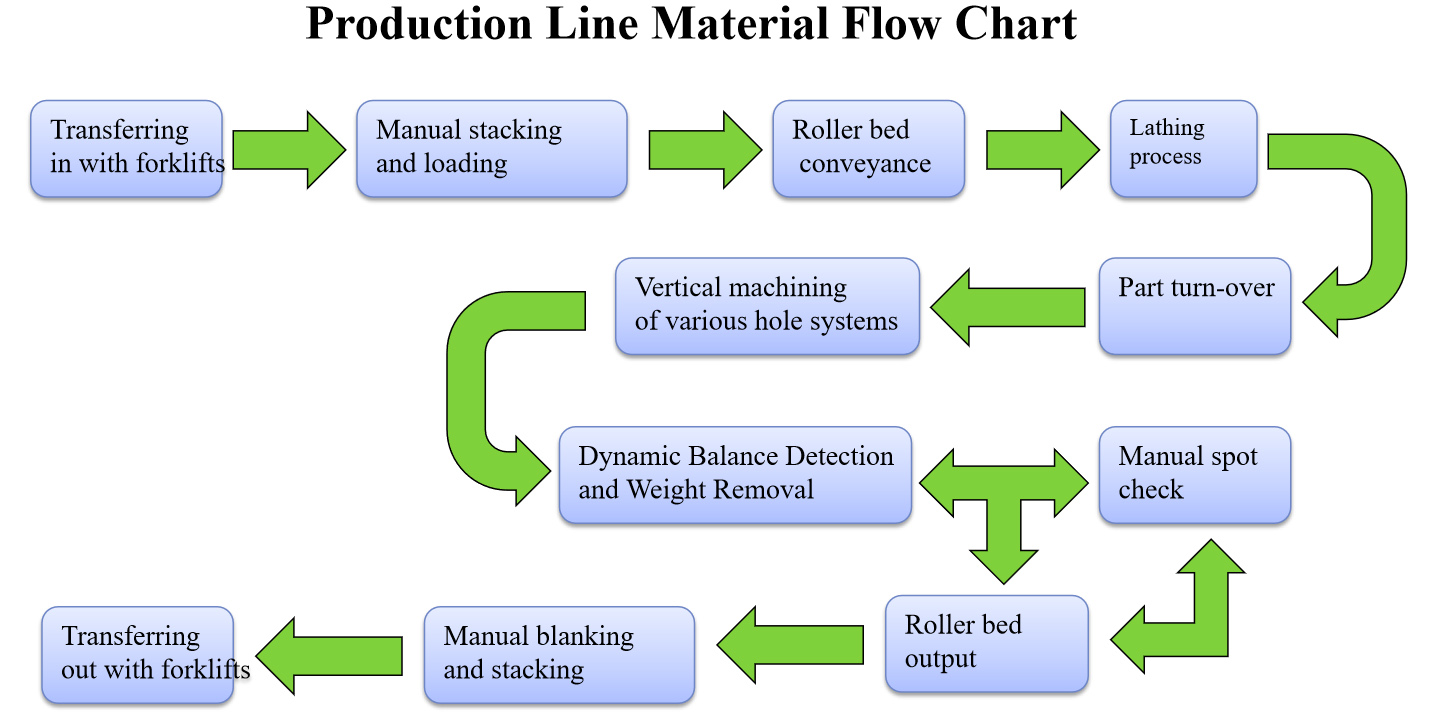

1. Cov chaw ua haujlwm tau raug thauj mus rau qhov chaw thauj khoom los ntawm forklifts, hoisted manually mus rau lub txaj menyuam txaj, thiab xa mus rau cov chaw thau khoom los ntawm cov menyuam. Kev thauj khoom thiab kev tshem tawm ntawm lub tshuab ntsuas hauv cov txheej txheem tshuab dhos, cov txheej txheem yob-dhau thiab cov txheej txheem drilling thiab milling yog ua tiav los ntawm cov neeg hlau. Cov khoom tiav raug xa mus rau qhov chaw blanking los ntawm cov menyuam txaj, thiab xa tawm los ntawm lub forklifts tom qab manually hoisting thiab stacking;

2. Cov ntxaij vab tshaus hluav taws xob loj loj yuav tsum tau teeb tsa ntawm cov kab xa khoom xa mus los hloov kho thiab tso saib cov ntaub ntawv ntawm cov khoom tsim tawm, cov khoom tsis raug thiab cov hnub tsim khoom muaj kev nyab xeeb hauv lub sijhawm;

3. Cov kab sib kis yuav tsum muaj lub teeb ceeb toom ntawm txhua lub tsev, uas tuaj yeem pom cov ntaub ntawv xws li kev ua ib txwm muaj, tsis muaj khoom siv thiab ceeb toom;

4. Tsis siv neeg kab txais kev ua vaj huam sib luag hom thiab ntau lub tsev thaiv kab, nrog kev hloov pauv tau yooj yim, tsim nyog rau cov kev xav tau sib txawv ntawm cov neeg siv khoom;

5. Txais cov neeg hlau sib koom ua ke rau kev thauj khoom thiab blanking, uas muaj kev ruaj ntseg siab, kev saib xyuas yooj yim thiab kev pab lub neej ntev;

6. Kev thov me me rau cov neeg ua haujlwm. Cov neeg ua haujlwm niaj hnub xav tau rau txhua qhov kev hloov pauv ntawm cov kab tsis siv neeg no yog raws li hauv qab no:

Forkliftman 1 ~ 2 tus neeg (tus saib xyuas nqa, forklifting thiab hloov chaw ua haujlwm / cov khoom tiav)

Maintenance Engineer 1 tus neeg (nyob rau hauv kev saib xyuas niaj hnub - roj thiab dej txiav, thiab lwm yam)

7. Cov kab tsis siv neeg muaj zog extensibility. Xws li sib xyaw hlau machining, workpiece traceability thiab lwm yam dej num, nrog tsawg expansion nqi;

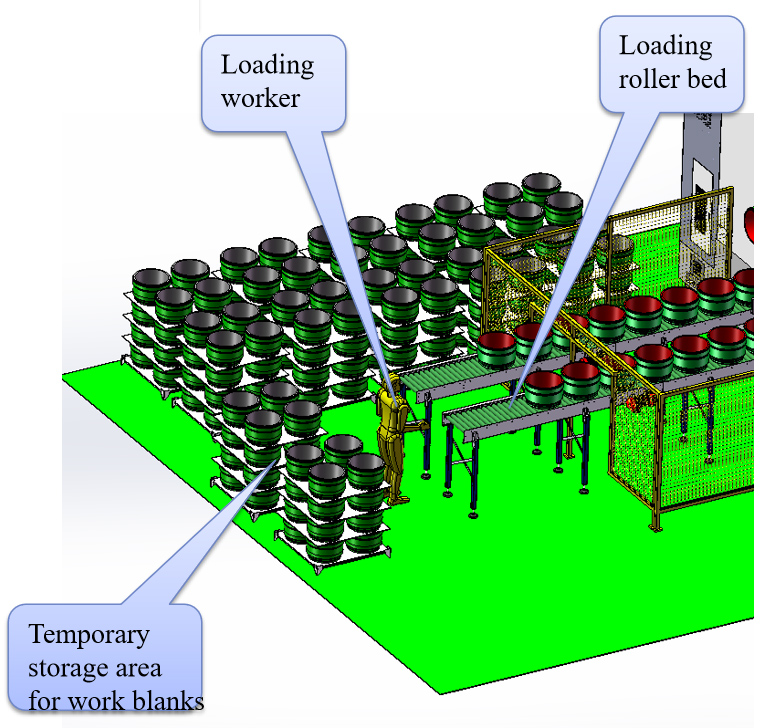

Chaw thau khoom unit

1. Cov khoom thauj cov menyuam txaj kab tuaj yeem khaws 12 × 16 = 192 daim; 2. Manually qhib lub pawg thiab hoist nws mus rau lub loading menyuam txaj thiab xa mus rau lub chaw thau khoom los ntawm cov menyuam conveyor; 3. Tom qab qhib cov pawg, lub tais khoob yuav tsum tau muab khi thiab muab tso rau ntawm txoj kab khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob khoob Kev thauj cov menyuam txaj kab tuaj yeem khaws 12 × 16 = 192 daim;

2. Manually qhib lub pawg thiab hoist nws mus rau lub loading menyuam txaj thiab xa mus rau lub chaw thau khoom los ntawm cov menyuam conveyor;

3. Tom qab qhib cov pawg, lub tais khoob yuav tsum tau muab khi thiab muab tso rau ntawm txoj kab uas hla ntawm cov tais khoob, muab tso rau hauv 8 txheej, thiab cov tais khoob khib nyiab yuav tsum tau muab tshem tawm manually thiab muab tso rau hauv qhov chaw cia khoom;

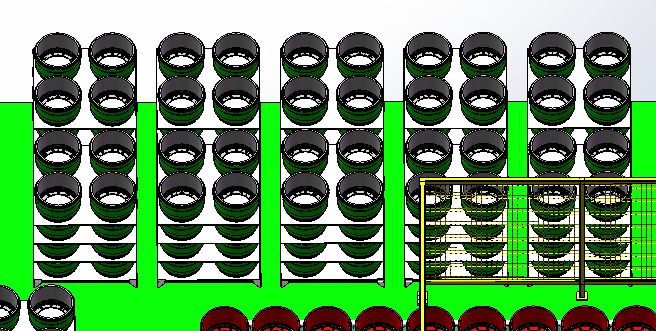

Taw qhia rau kev ua haujlwm dawb pawg

1. Ib pawg ntawm 16 daim thiab 4 txheej hauv tag nrho, nrog rau kev faib cov phaj ntawm txhua txheej;

2. Lub chaw ua haujlwm dawb paug tuaj yeem khaws 160 daim;

3. Lub pallet tau pom zoo kom npaj los ntawm tus neeg siv khoom. Yuav tsum tau: (1) Zoo rigidity thiab flatness (2) yuav tsum tau clamped los ntawm tus neeg hlau.

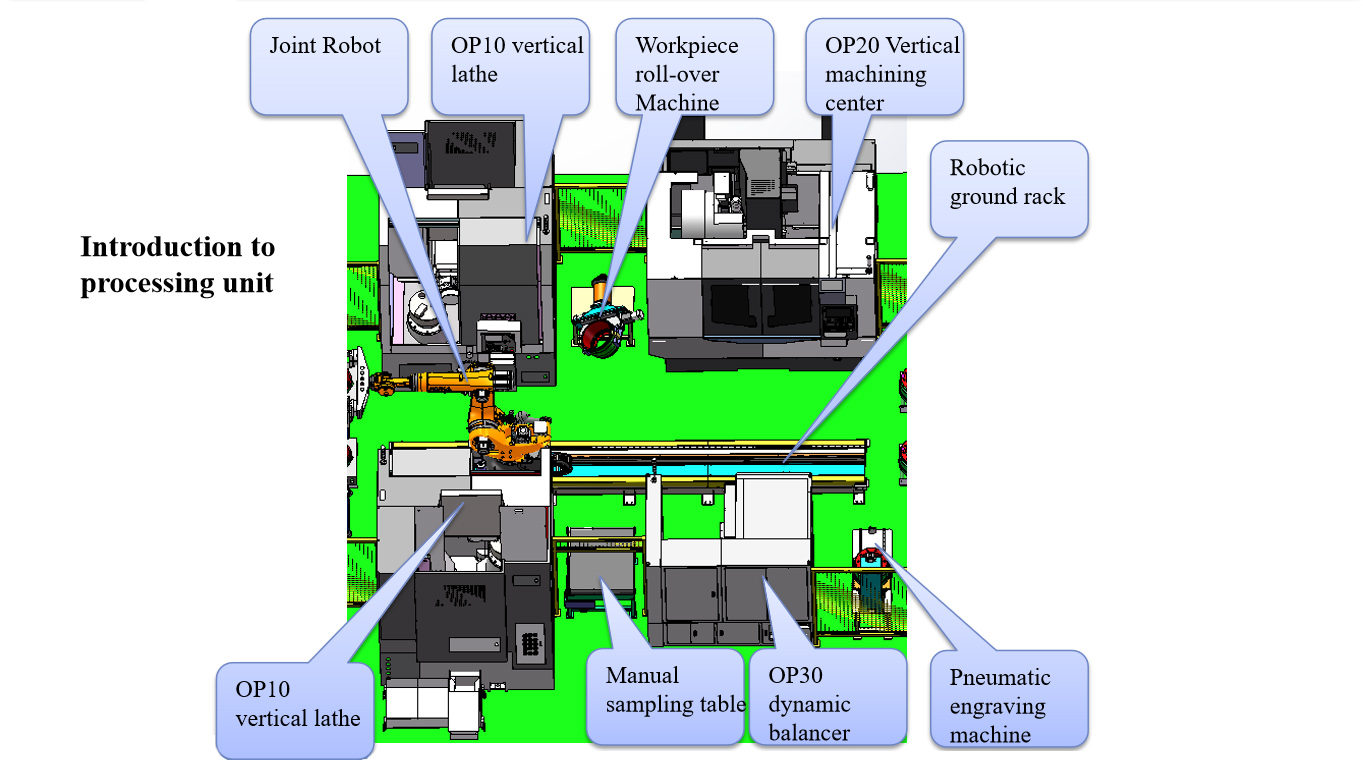

Taw qhia txog kev ua haujlwm

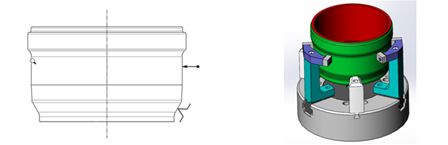

1. Cov txheej txheem lathing muaj ob lub tshuab dhos ntsug, No. 1 neeg hlau thiab cov neeg hlau hauv av khib, uas ua haujlwm rau kev ua haujlwm ntawm lub voj voog sab nrauv, sab hauv lub qhov kauj ruam nto thiab lub ntsej muag kawg ntawm qhov;

2. Roll-over chaw nres tsheb muaj 1 dov tshaj lub tshuab, uas ua haujlwm tsis siv neeg dov ntawm qhov chaw;

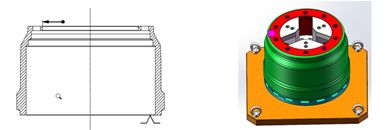

3. Lub drilling thiab milling txheej txheem muaj 1 ntsug machining chaw thiab ib tug No.

4. Cov txheej txheem dynamic balancing thiab hnyav tshem tawm muaj ib tug ntsug dynamic balancer, uas undertakes dynamic balancing nrhiav kom tau thiab tshem tawm qhov hnyav ntawm qhov chaw;

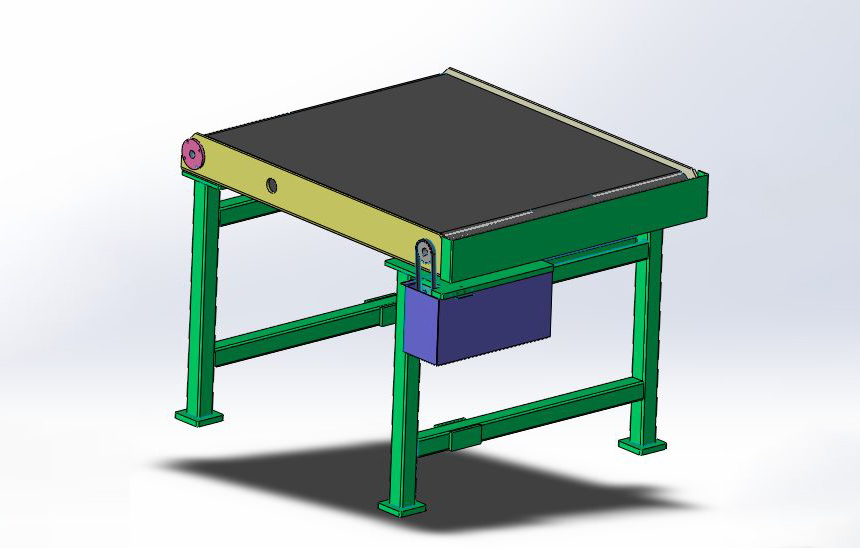

5. Lub chaw kuaj xyuas qhov chaw siv phau ntawv muaj ib txoj siv conveyor, uas ua haujlwm thauj khoom ntawm qhov chaw kuaj xyuas qhov chaw thiab siv los ua qhov chaw kuaj xyuas;

6. Lub chaw ua hauj lwm ntawm lub tshuab pneumatic engraving ua hauj lwm ntawm engraving thiab cim tag nrho cov khoom;

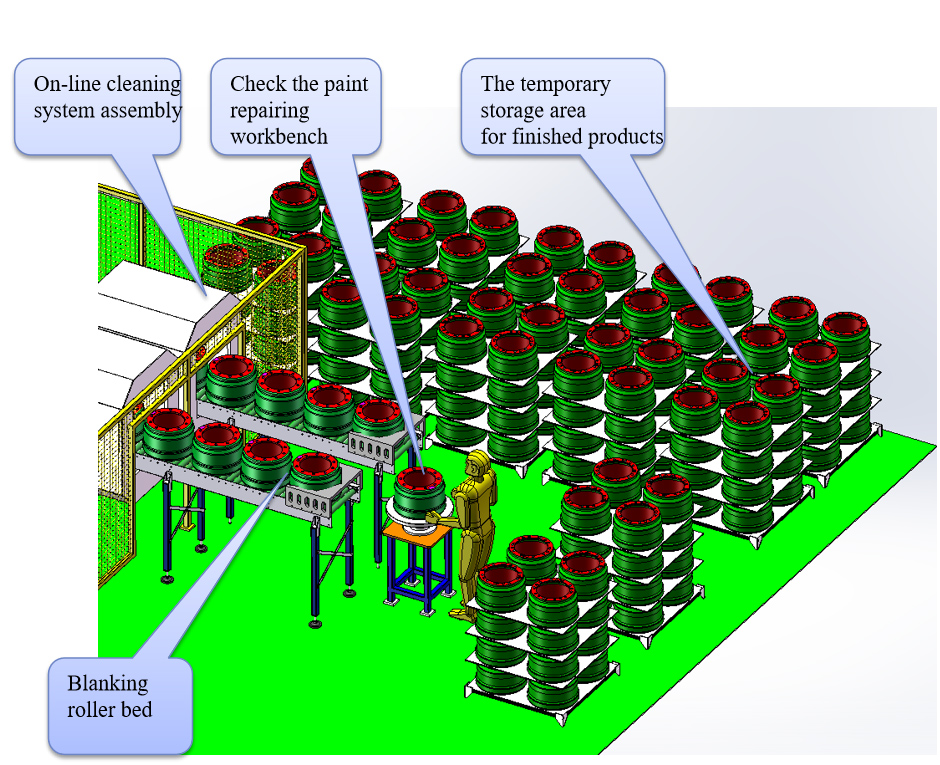

Taw qhia ntawm lub blanking unit

1. Cov khoom thauj cov menyuam txaj kab tuaj yeem khaws 12 × 16 = 192 daim;

2. Cov tais thiab cov phaj sib faib ntawm qhov chaw nres tsheb thauj khoom yog thauj mus rau thaj chaw blanking los ntawm forklifts;

3. Cov khoom tiav raug thauj mus rau qhov chaw nres tsheb blanking los ntawm cov menyuam conveyor, thiab hoisted thiab stacked manually thiab pauv nrog forklifts;

Taw qhia txog cov khoom tiav stacking

1. Ib pawg ntawm 16 daim thiab 4 txheej hauv tag nrho, nrog rau kev faib cov phaj ntawm txhua txheej;

2.192 daim tuaj yeem khaws cia rau hauv pawg ntawm cov khoom tiav;

3. Lub pallet tau pom zoo kom npaj los ntawm tus neeg siv khoom. Yuav tsum tau: (1) Zoo rigidity thiab flatness (2) yuav tsum tau clamped los ntawm tus neeg hlau.

Taw qhia txog cov khoom tseem ceeb ntawm cov kab ntau lawm

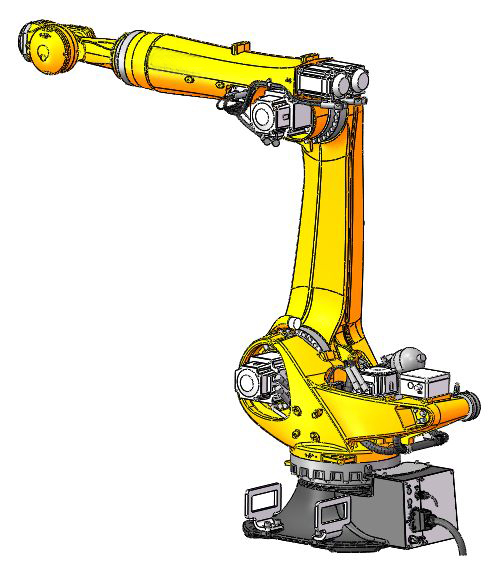

Introduction to Machining and Dynamic Balancing Weight Removal Unit Robot

Chenxuan neeg hlau: SDCX-RB08A3-1700

| Cov ntaub ntawv yooj yim | |

| Hom | SDCX-RB08A3-1700 |

| Tus naj npawb ntawm axes | 6 |

| Qhov siab tshaj plaws | 3100 hli |

| Pose repeatability (ISO 9283) | ± 0.05 hli |

| Qhov hnyav | 1 134kg |

| Kev tiv thaiv kev faib tawm ntawm cov neeg hlau | Kev tiv thaiv ntsuas, IP65 / IP67hauv kab dab teg(IEC 60529) |

| Mounting txoj hauj lwm | Qab nthab, tso cai lub kaum sab xis ntawm inclination ≤ 0º |

| Nto tiav, pleev xim | Lub hauv paus ncej: dub (RAL 9005) |

| Ambient kub | |

| Kev ua haujlwm | 283 K txog 328 K (0 ° C txog + 55 ° C) |

| Kev khaws cia thiab kev thauj mus los | 233 K txog 333 K (-40 ° C txog + 60 ° C) |

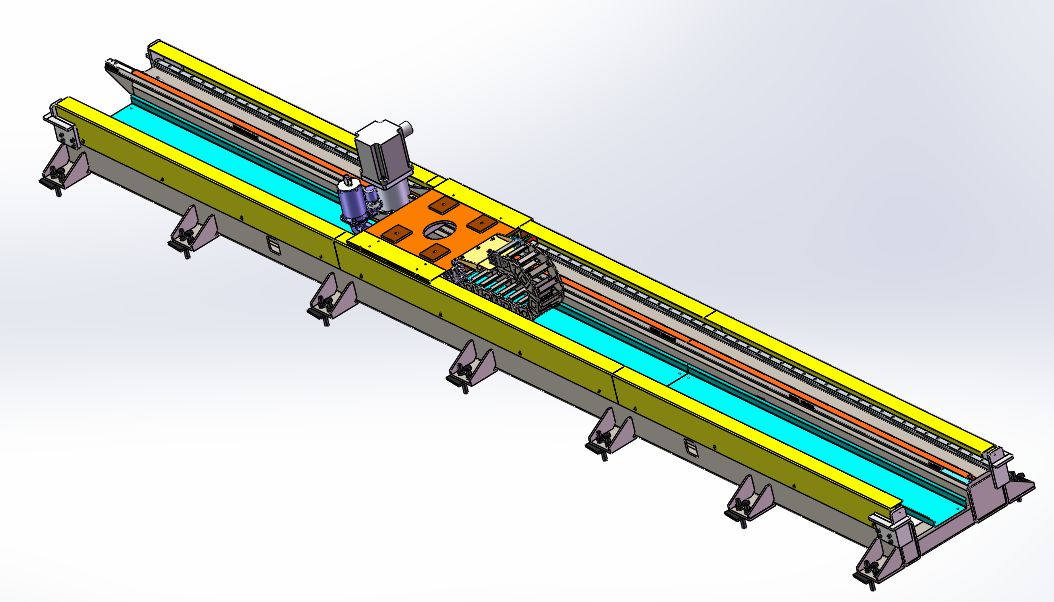

Taw qhia ntawm Robot Travel Axis

Cov qauv yog tsim los ntawm cov neeg hlau sib koom ua ke, lub servo lub cev muaj zog tsav thiab lub pinion thiab khib tsav, kom cov neeg hlau tuaj yeem ua cov lus tsa suab rov qab. Nws paub txog kev ua haujlwm ntawm ib tus neeg hlau ua haujlwm rau ntau yam cuab yeej siv tshuab thiab tuav cov khoom ua haujlwm ntawm ntau qhov chaw nres tsheb thiab tuaj yeem ua kom muaj kev sib koom ua haujlwm ntawm cov neeg hlau sib koom ua ke;

Kev taug kev taug kev siv lub hauv paus welded nrog cov kav hlau thiab yog tsav los ntawm servo lub cev muaj zog, pinion thiab khib tsav, txhawm rau txhim kho kev ua haujlwm ntawm cov neeg hlau sib koom ua ke thiab txhim kho kev siv tus nqi ntawm cov neeg hlau;

Txoj kev taug kev yog ntsia rau hauv av;

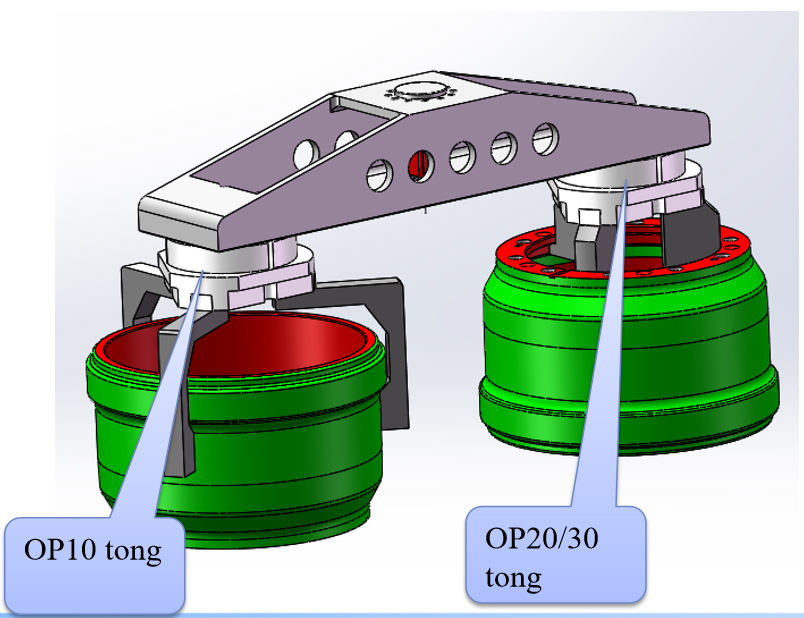

Kev taw qhia txog cov ntiv tes ntawm kev thauj khoom thiab blanking robots

Nqe lus piav qhia:

1. Raws li tus yam ntxwv ntawm qhov no, peb txais peb-claw sab nraud yoj nto;

2. Lub tshuab yog nruab nrog txoj haujlwm nrhiav kom pom thiab lub siab ntsuas ntsuas seb qhov clamping li cas thiab qhov siab ntawm qhov chaw yog qhov qub;

3. Lub tshuab yog nruab nrog lub tshuab pressurizer, thiab lub workpiece yuav tsis poob rau hauv ib lub sij hawm luv luv nyob rau hauv cov ntaub ntawv ntawm lub hwj chim tsis ua hauj lwm thiab gas cut-off ntawm lub ntsiab cua Circuit Court;

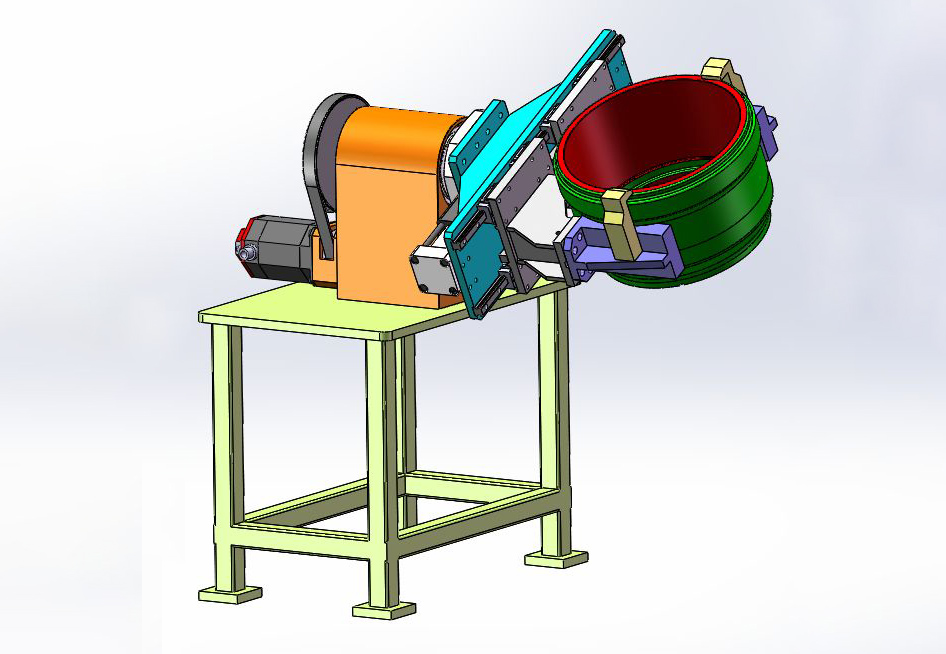

Taw qhia ntawm Automatic Roll-over Machine

Nqe lus piav qhia:

Lub tshuab yog tsim los ntawm ib lub thav duab ruaj khov, lub hauv paus kev txhawb nqa thiab lub pneumatic tong sib dhos. Nws muaj kev tiv thaiv xoob thiab tiv thaiv kev poob qis tom qab kev txiav tawm huab cua, thiab tuaj yeem paub txog 180 ° yob ntawm kab ua haujlwm;

Taw qhia rau phau ntawv chaw kuaj lub rooj zaum

Nqe lus piav qhia:

1. Teem caij sib txawv ntawm phau ntawv random sampling zaus rau cov theem ntau lawm, uas tuaj yeem tswj xyuas qhov ua tau zoo ntawm kev ntsuas hauv online;

2. Cov lus qhia rau kev siv: Lub manipulator yuav muab lub workpiece mus rau lub teeb nyob rau hauv qhov chaw ntawm lub rooj zaum check raws li lub zaus teem manually, thiab sai li sai tau nrog lub teeb liab. Tus neeg kuaj xyuas yuav nias lub pob kom thauj cov khoom ua haujlwm mus rau qhov chaw nyab xeeb sab nraum qhov kev tiv thaiv, tshem tawm cov khoom ua haujlwm rau kev ntsuas thiab xa rov qab mus rau lub txaj menyuam tom qab ntsuas;

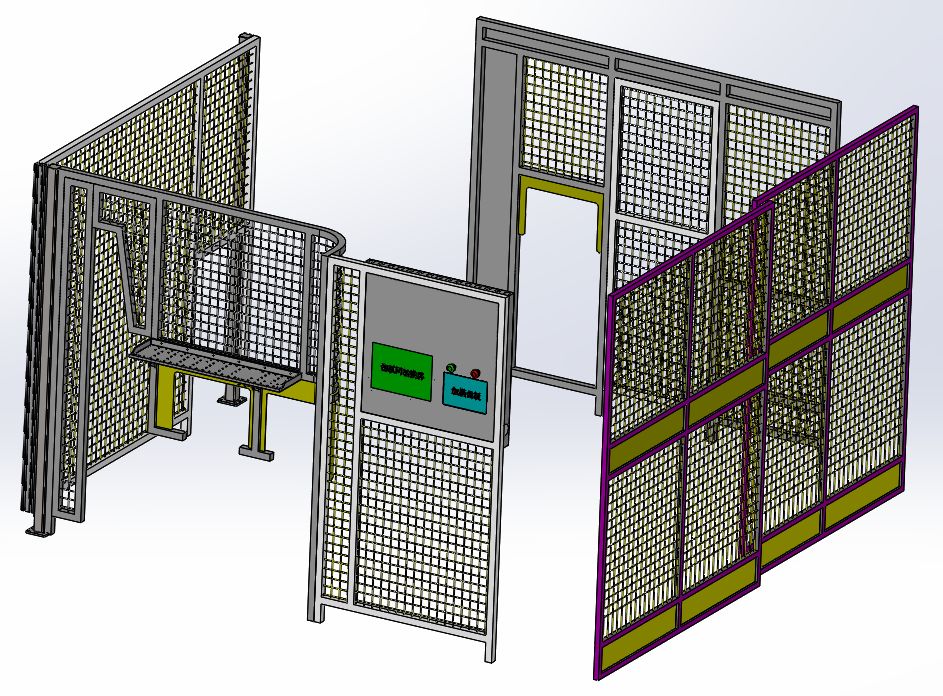

Cov khoom tiv thaiv

Nws yog tsim los ntawm lub teeb yuag aluminium profile (40 × 40) + mesh (50 × 50), thiab lub vijtsam kov thiab khawm nres thaum muaj xwm ceev tuaj yeem ua ke rau hauv cov khoom tiv thaiv, kev sib koom ua ke kev nyab xeeb thiab kev zoo nkauj.

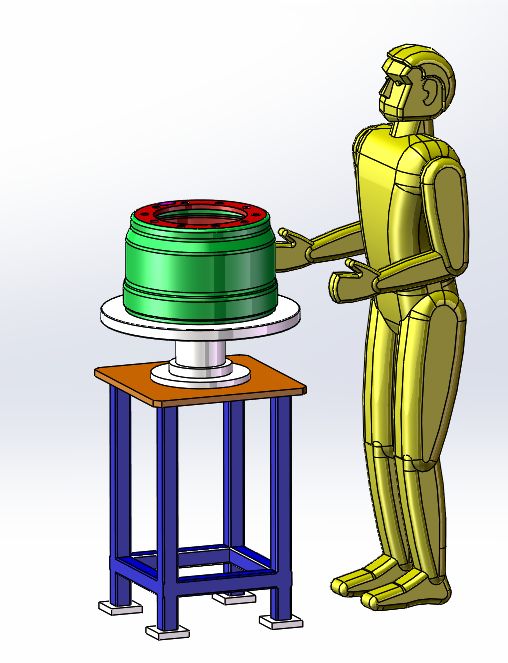

Taw qhia rau Lub Chaw Saib Xyuas Kev Tshawb Fawb rau kev kho xim

Nqe lus piav qhia:

Lub mechanism yog tsim los ntawm ib tug ruaj thav duab thiab ib tug turntable. Cov neeg ua haujlwm nqa cov khoom tiav mus rau lub turntable, tig lub turntable, xyuas seb puas muaj pob, khawb thiab lwm yam tshwm sim, thiab kho raws sij hawm kho qhov tsis xws luag thiab cov xim pleev xim;